6 Easy Steps to Testing Clutches with your Ames Portable Hardness Tester

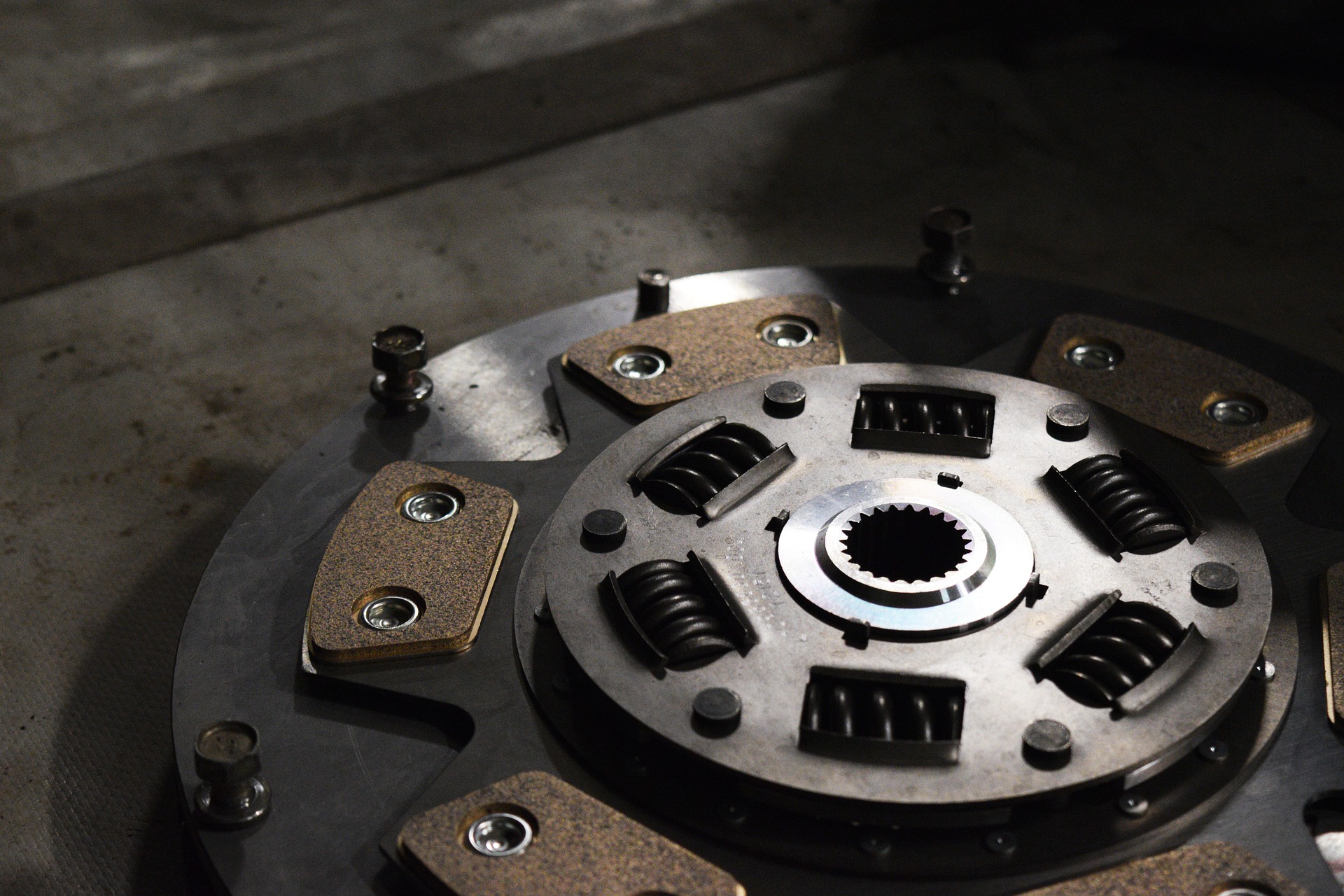

Your Ames Portable Hardness Tester was designed for checking the hardness of materials in the Rockwell scales. This has become an asset to the racing industry which has developed a scale* for checking clutches using the Ames Portable Hardness Tester. The Ames tester helps to win races by providing repeatable results every time.

Featured in one of our promotions, Mike Bell, team II driver for Roy Hill Drag Racing, knows how important clutch plate survival is to victory in Pro Stock. Sudden heating can affect both surface and internal structure of clutch metals. Mike used Ames Rockwell Hardness Tester model 2 to check surface hardness of both plates before installation. He used the following recommended configuration. Roy Hill Drag Racing’s Ford Thunderbird set a Pro Stock National record of 6.73 seconds in 1995.

They provide the following recommendations for testing clutches* with your hardness tester in 6 easy steps:

To get yourself set up, make sure you have the following items: Model 2 Ames Portable Tester with a 1-inch anvil and 1/2 inch ball penetrator.

Step 1: Rotate the outer ring on the dial indicator and align the “dot” directly under the indicator needle. Position the clutch between the 1/2 inch ball penetrator and the 1-inch anvil. Make sure the surface is flat and the ball will not fall into holes or grooves.

Step 2: Rotate the handwheel clockwise until the needle on the gauge moves to the set position on the gauge face.

Step 3: Rotate the aluminum barrel counterclockwise so that the pin rests on top of the lucite magnifier

Step 4: Rotate the handwheel clockwise until the indicator needle reaches 60 on the indicator face.

Step 5: Immediately rotate the handwheel counterclockwise until the indicator is back at the set position.

Step 6: Read the black scale on the barrel. The thick line across the barrel is the whole number. (10, 20, 30, 40 etc.) The smaller hash marks on the left side of the barrel are in two-point increments.

Note: It has been established that using this method, test readings that fall between 65 to 80 give the best results.

You probably recognize former racing customers such as Massey Race Cars, Wayne County Speed, Stouts, Carl Smith, Glidden Racing, Ricky Smith Racing, Paul Rebeschi, Gary Brown Racing, Heck Racing, and Nickens Bros. Racing maintenance crews have come to rely on the results provided by Ames hardness testers.

*Please note that this is a special testing method designed by professionals in the racing industry for use as described in these steps and does not represent recommended testing methods for our Ames Portable Hardness Testers. In this case, the ball penetrator is used and the “B” scale is read. The ball penetrator is not used to produce readings in the “B” scale.