Accurately Reading a Rockwell Portable Hardness Tester

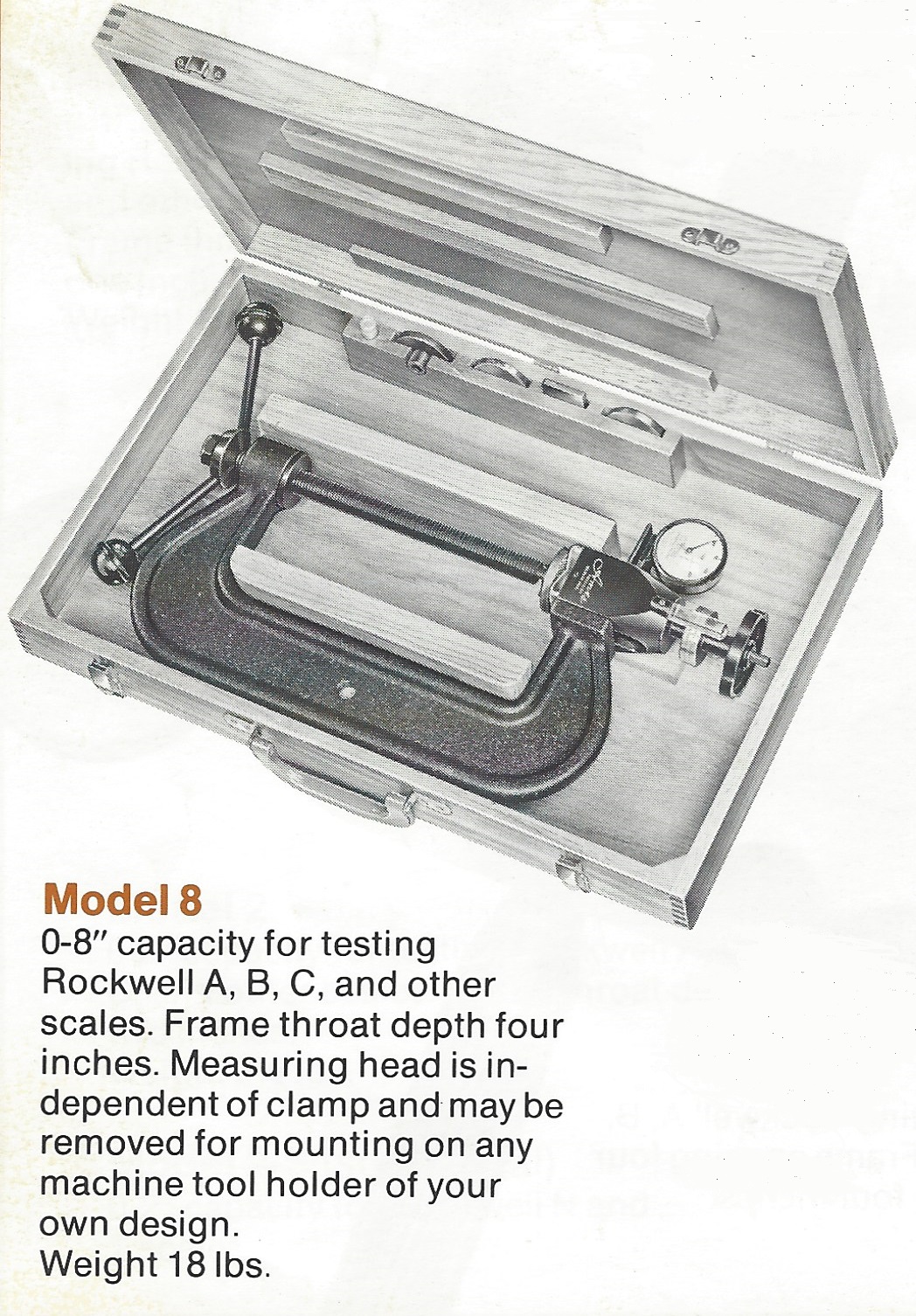

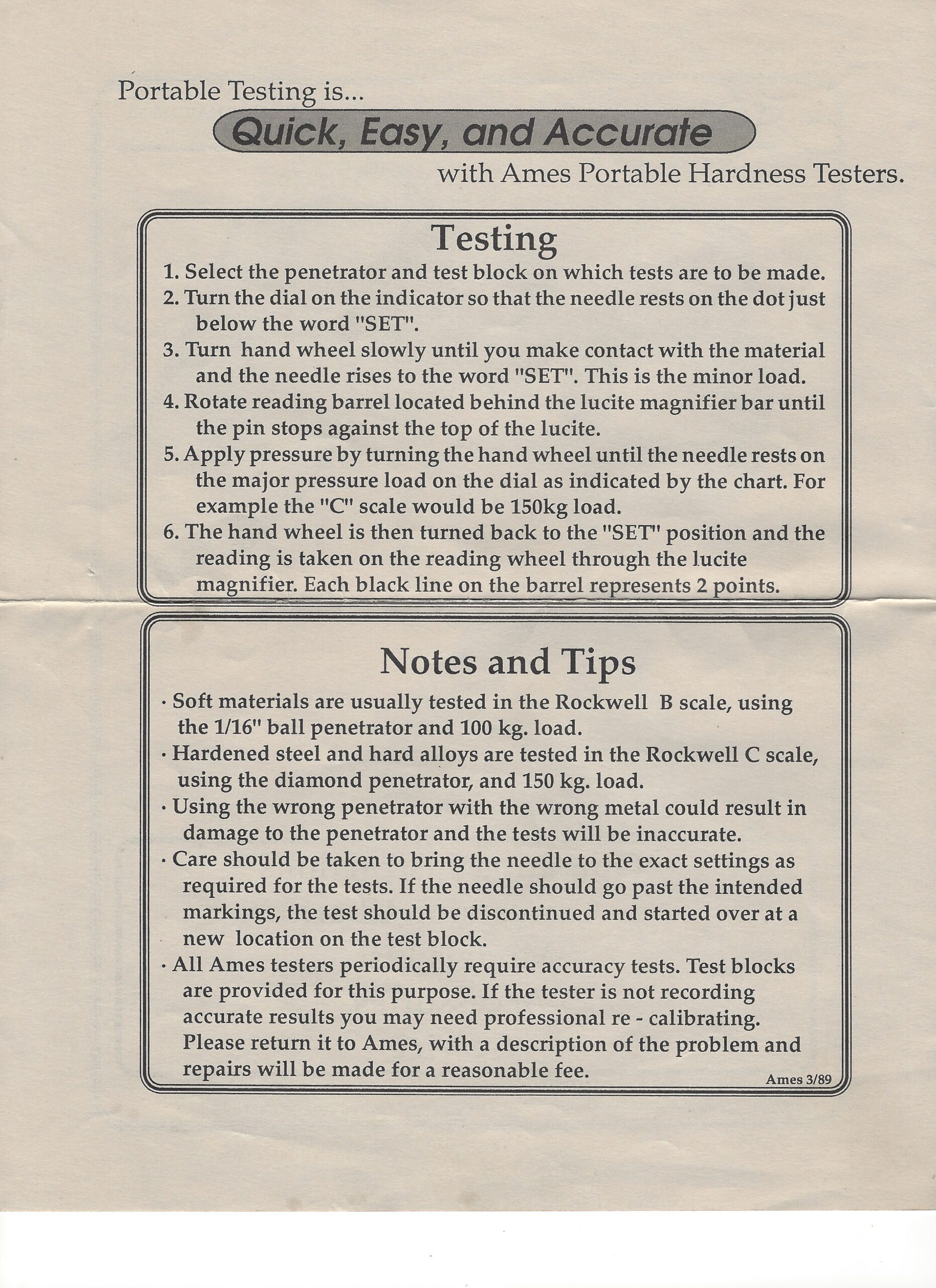

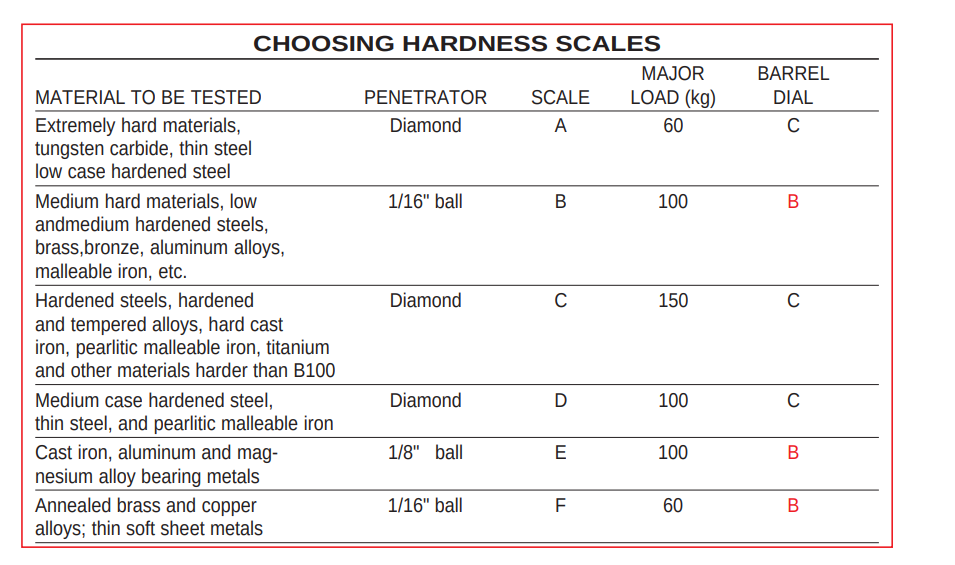

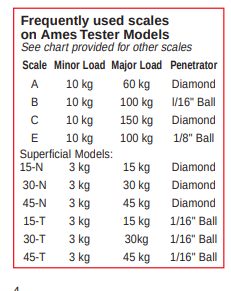

When you get a new Ames tester, it is important to practice with it as you would with any other measuring instrument. Ames accuracy testing helps you ensure that your hardness tester is reading accurately. Using your test blocks to verify the correct readouts on your Ames tester ensures the tester is working as it should. Making sure you are reading your Ames tester accurately is also important. Frequently used scales on Standard hardness testers are A, B, C, and E in the Rockwell scale. Superficial scales that are frequently used include 15-N, 30-N, 45-N, 15-T, 30-T, and 45-T. Familiarize yourself with charts for these scales and practice testing in the scale you will be using most frequently.

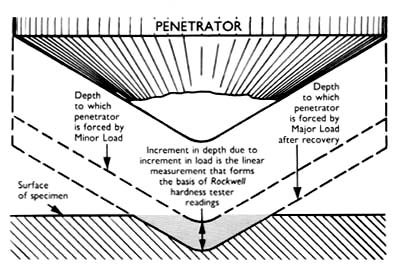

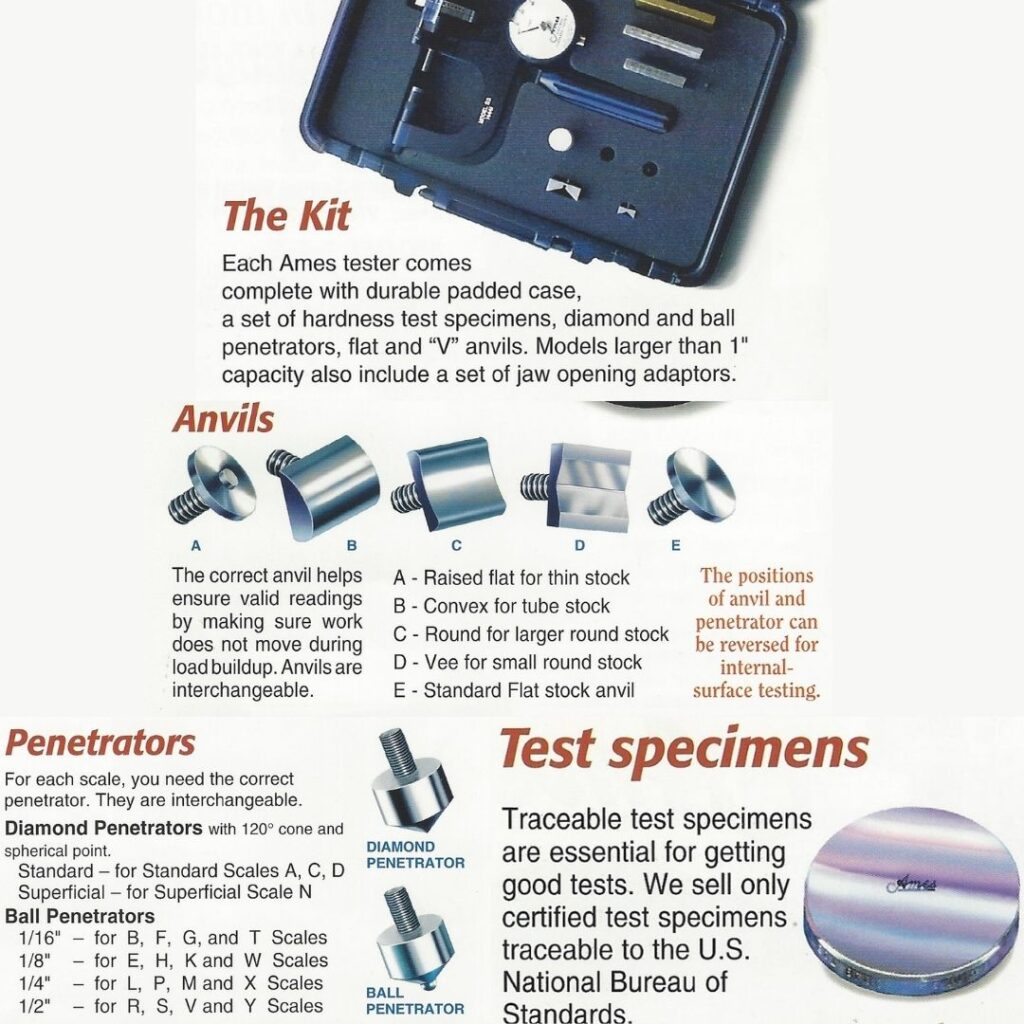

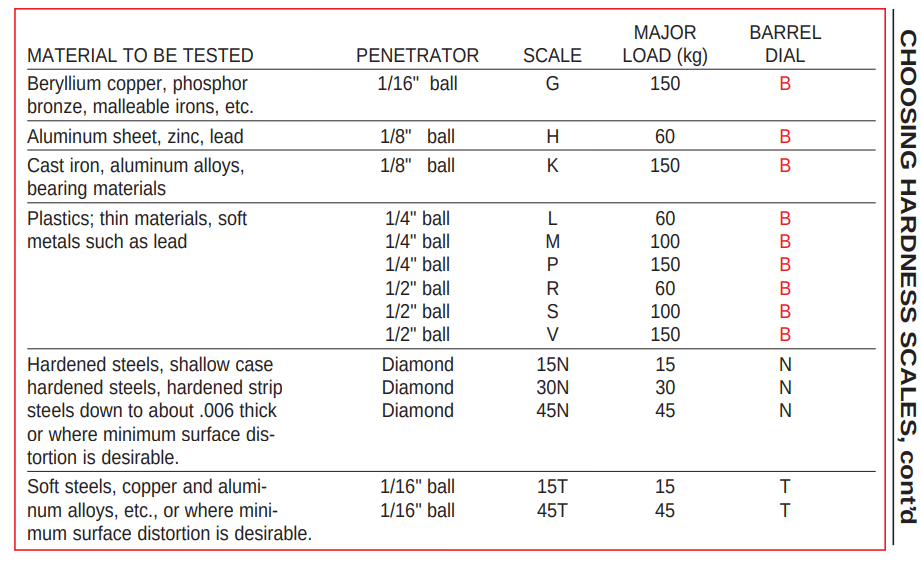

There are two basic types of penetrators that you will be using to conduct your hardness tests. The ball penetrator comes in 4 sizes, be sure to check your chart for the appropriate penetrator. For example, if you are testing a soft material, you will likely be testing in the “B” scale and will use a 1/16″ ball penetrator. Never use the ball penetrator with your steel test block or when testing hard steel, this will damage your penetrator and give invalid results. For testing harder materials, you will use a diamond penetrator. Diamond penetrators are available for either a standard or superficial tester, all one size. Using the diamond penetrator on a softer material can ruin your material. If you are testing a harder material you will likely test in Rockwell C with the diamond penetrator.

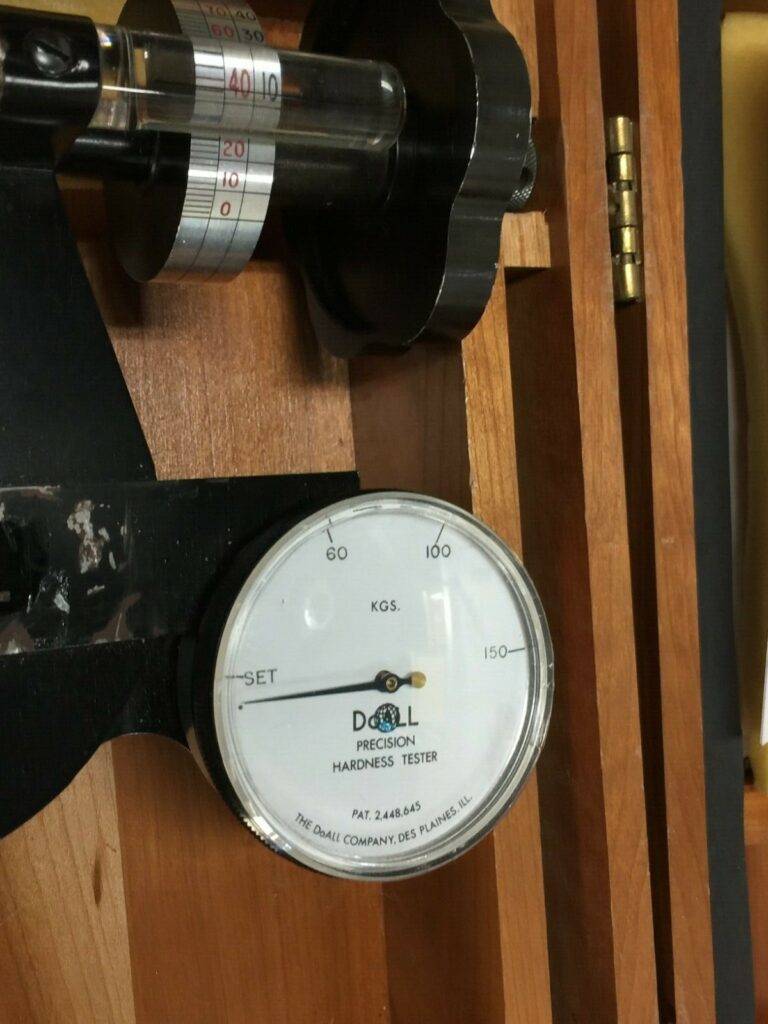

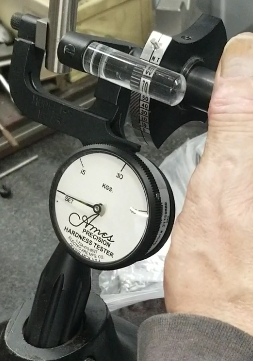

When you set up your tester, be sure to secure the penetrator and the appropriate anvil. Check the position of the indicator hand. The indicator should rest directly on the dot on the dial. When you apply the minor load, slowly turn the hand wheel until the indicator points to the line marked “set”. Next, you will rotate the top of the barrel dial toward you until the pin rests against the magnifier. If you are using a model 1-4, there is no pin and you will need to align visually. Your Ames manual contains these instructions.

When you apply the major load, turn the hand wheel until the pointer rests on the major load indicated by the chart. You need to be careful to bring the indicator exactly to the desired graduation on the dial. If penetration goes beyond the major load you will not receive a valid reading and will not be able to receive a valid reading on that penetration. You will need to choose a new test point and begin the test again.

When you turn the handwheel back and bring the pointer back to “set” you can take the reading through the magnifier. Each graduation indicates two points on the Rockwell scale. If you are using a standard tester with a ball penetrator, read the black numbers in column “B”. If you are using a diamond penetrator, read the black numbers in column “C”. You may notice the first two or three tests may be low until your penetrator and anvil are seated.

In addition to practice and accuracy testing, it is important that you have your hardness tester calibrated at our facility on an annual basis.