Hardness Testing in Rockwell Scales

Hardness Testing – Rockwell scales

Rockwell Hardness testing is a system for determining the hardness of metals and alloys of all kinds. The American Society for Testing and Materials (ASTM) has established a standard recognized worldwide to help manufacturers maintain the qualities they want in their products. If you are using the Brinell scale check out our conversion chart.

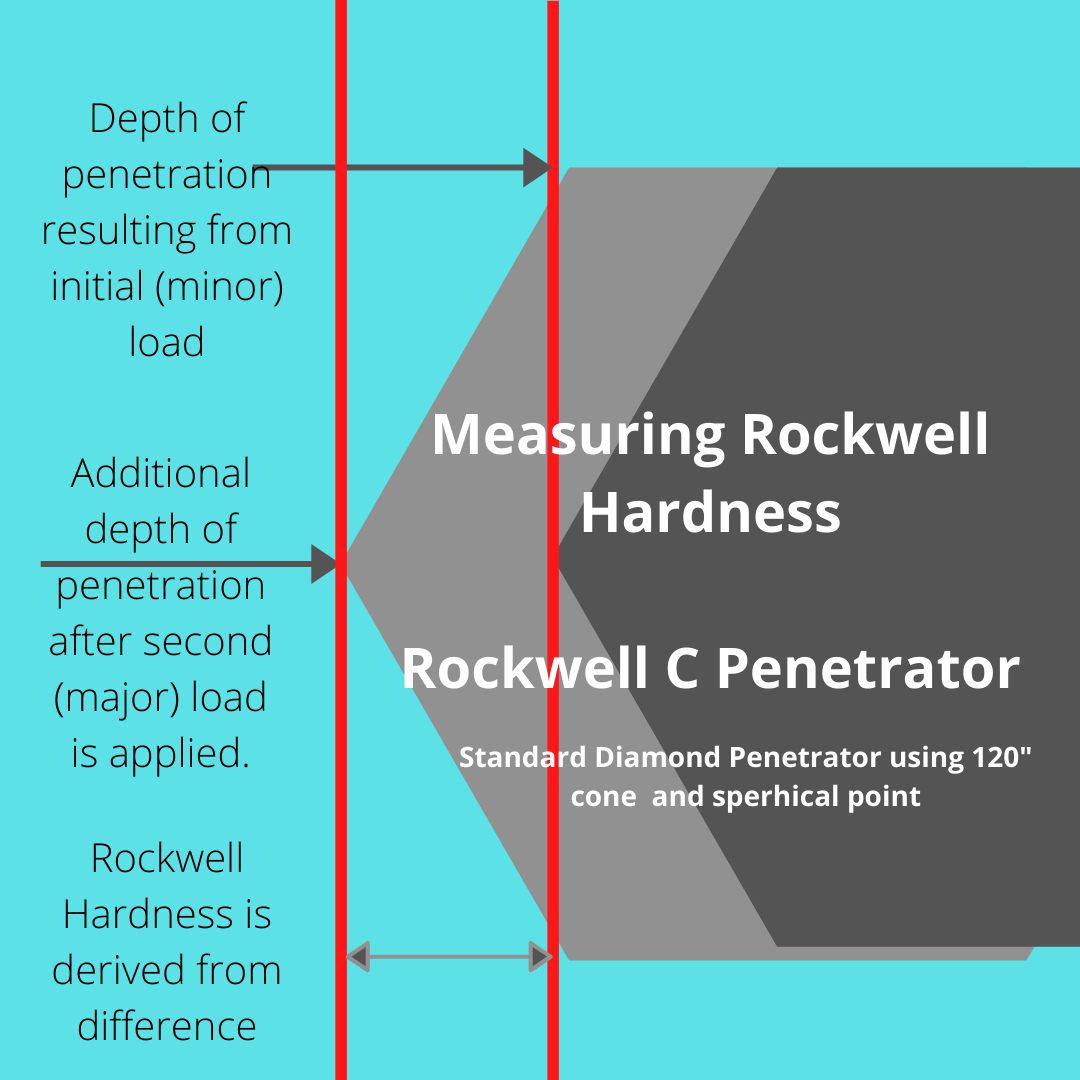

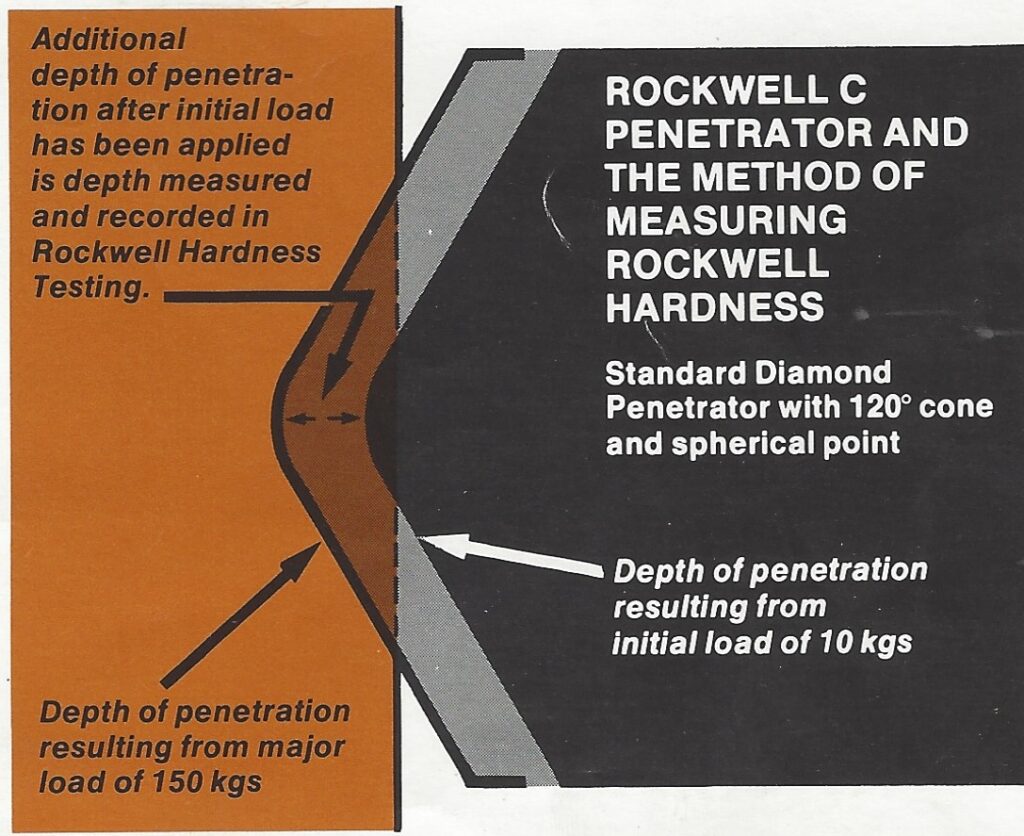

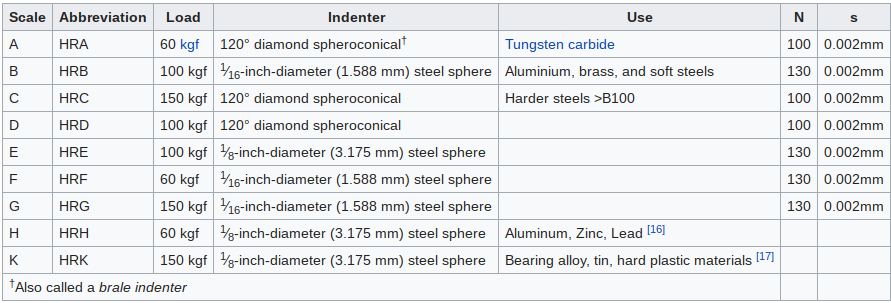

ASTM Standards E-18 and E-110 defines the test method and parameters for a valid test using portable hardness testers. Following is a general description of the method. A spheroconical diamond penetrator or a carbide ball penetrator is forced into the surface being tested at a predetermined pressure load. The hardness is read as a function of the depth of penetration.

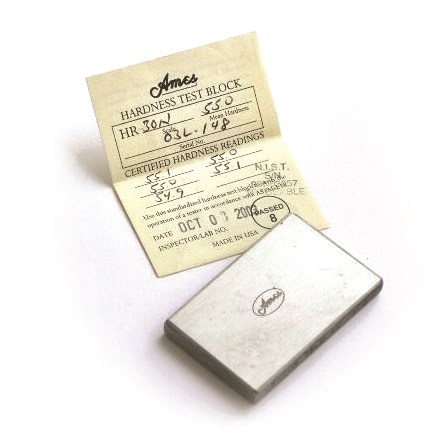

To overcome errors in measurement, two pressure loads are applied in sequence. The first, a minor load is applied and the readout dial is “zeroed” with the part being tested still under load. Then the major load is applied. The penetrator is backed out to the minor load point to read the distance traveled. The hardness reading represents the additional depth of penetration beyond the minor load. Tester accuracy is checked by running the test on specimens whose hardness has been certified by an independent testing laboratory. All Ames hardness testers perform genuine Rockwell Hardness tests, giving a direct Rockwell reading. Their accuracy meets or exceeds ASTM Standards E-18 and E-110. Each tester comes complete with test specimens to assure continued accuracy.

*All Ames testers are

factory lubricated. Do not

attempt additional lubrication.

Keep the tester dry and free

from oil. Store in the case

provided. When necessary,

wipe with a commercial

cleaner

Maintaining accuracy with a portable Rockwell hardness tester

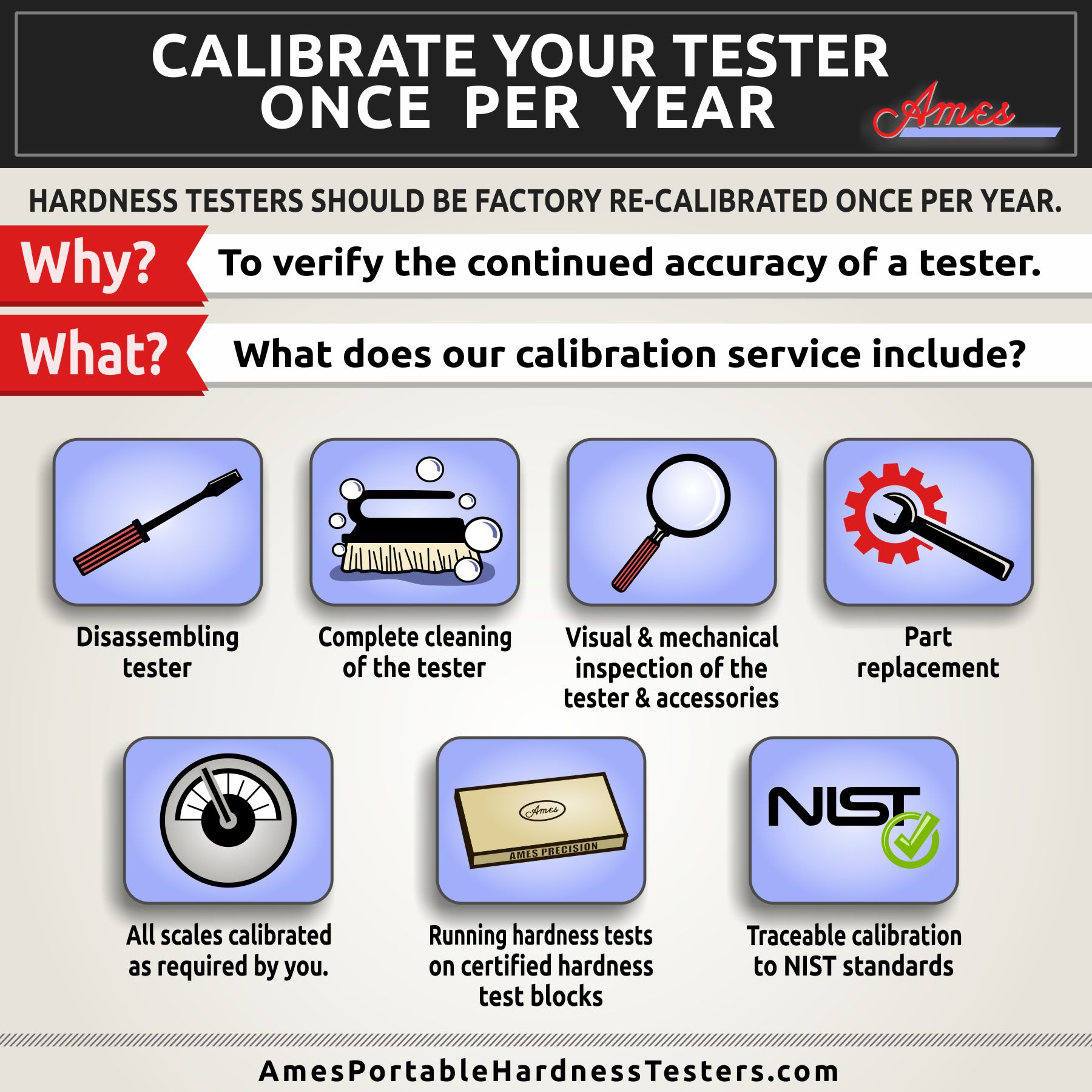

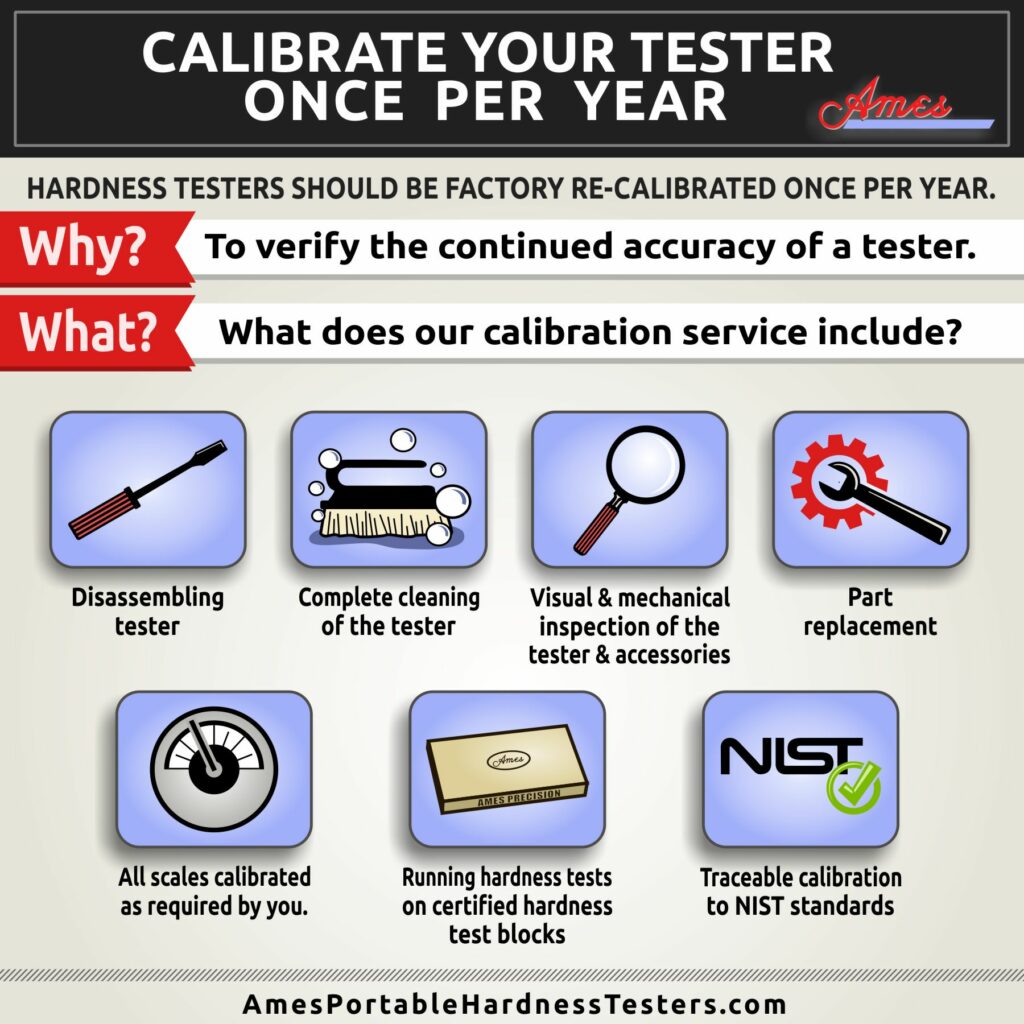

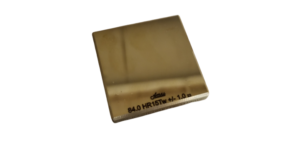

All AMES Hardness Testers, whether in constant use or not, require accuracy checks. To check accuracy, take the average of 5 readings on the test block. The readings on the barrel dial should agree with the marking on the test block, within +/- 1 point.

Further, to guarantee the accuracy of your tester, it is recommended that tests be made in high, medium, and low ranges. For example, C Scale, C-63, C-50, and C-28. Once per year, your tester needs to be factory calibrated.

The distance between the center of two adjacent indentations shall be at least three times the diameter of

the indentation. The distance from the center of any indentation to an edge of the test piece shall be at least two and a half times the diameter of the indentation. In other words, keep indentations 3 diameters apart. Indentations can only be made on one side of the test block.

Please check out our penetrators for hardness testing by clicking the link below

Also check out more on how to properly use a portable Rockwell tester by following the link below

How to properly use a Ames Rockwell Hardness Tester

You may also contact us with any questions you may have.

To ensure your Rockwell metal hardness tester is performing at it’s highest efficiency you should perform accuracy checks regularly.

To ensure your Rockwell metal hardness tester is performing at it’s highest efficiency you should perform accuracy checks regularly.