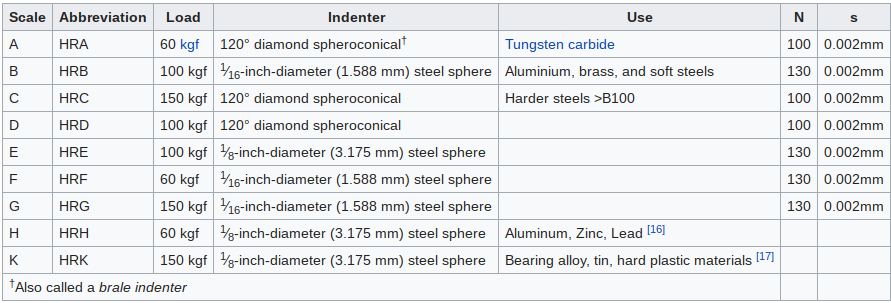

You can use the Rockwell hardness test to test the hardness of materials. You will use the Rockwell test to perform tests on metals ranging from thin steel all the way to harder metals like Titanium. However, there are multiple scales to test in and these are identified by a letter ranging from A-V Each scale uses a different indenter and load to perform the test.

When you perform a hardness test using the Rockewell scale, you can determine the hardness of metals and alloys of all kinds. You will use a sphero-conical diamond penetrator or a hard steel penetrator which is forced into the part being tested with a predetermined pressure load and the readings represent the hardness numbers.

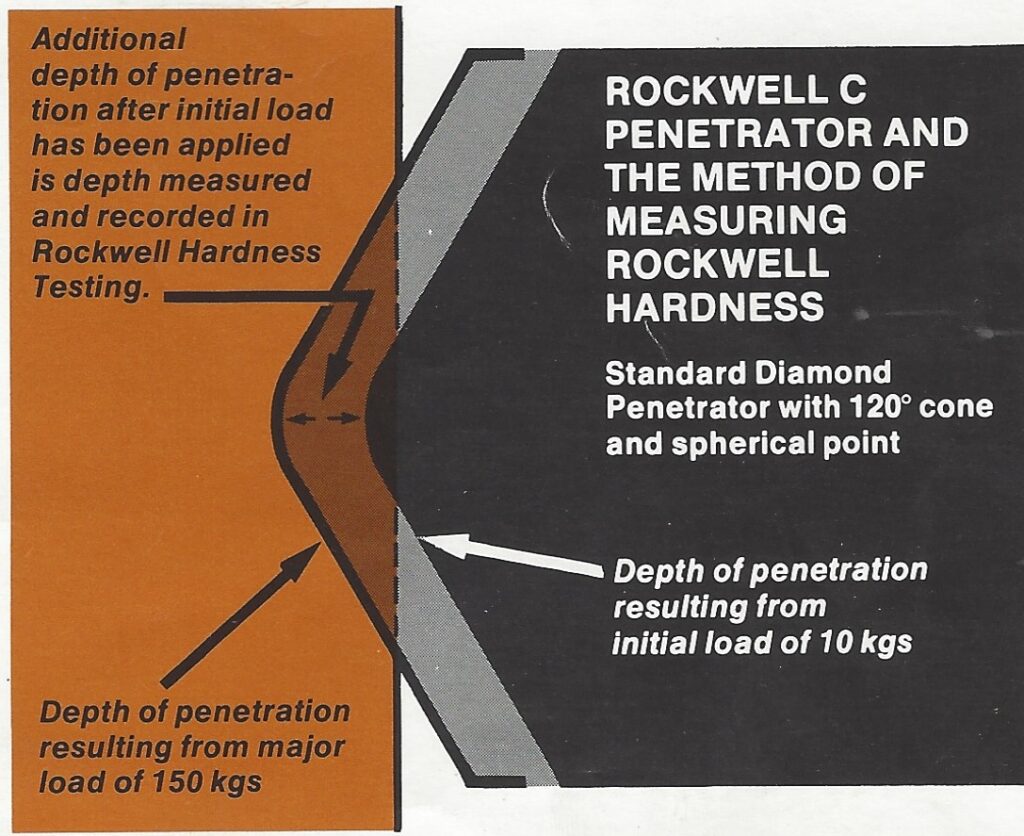

You can avoid errors in measurement due to surface imperfections or distortions at the periphery of the indentation with both minor and major loads. The minor load of 10 KGS is applied first. Remove the major load turning the handwheel back until the indicator hand is in position “set” on the dial. The reading is taken from the barrel dial, which completes the whole operation in a few seconds.

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below.

Rockwell A scale

Used to test: Tungsten carbide.

Rockwell B Scale

Used to test: aluminum, brass, and softer steels

Rockwell C Scale

Used to test: harder steels.

There are other scales that are associated with a Rockwell superficial test. These scales use a lighter loads and shallow impressions to perform the test. These are used on testing very thin metals.

Ames Superficial Hardness Tester

Note: There is only one row of dial numbers for the Ames superficial tester.

[…] or bench and portable hardness testers. The operating principle of stationary hardness testers on Rockwell scales are described in the standards on the corresponding methods. Hardness tests on stationary hardness […]