Using your Ames Rockwell – Brinell Conversion table

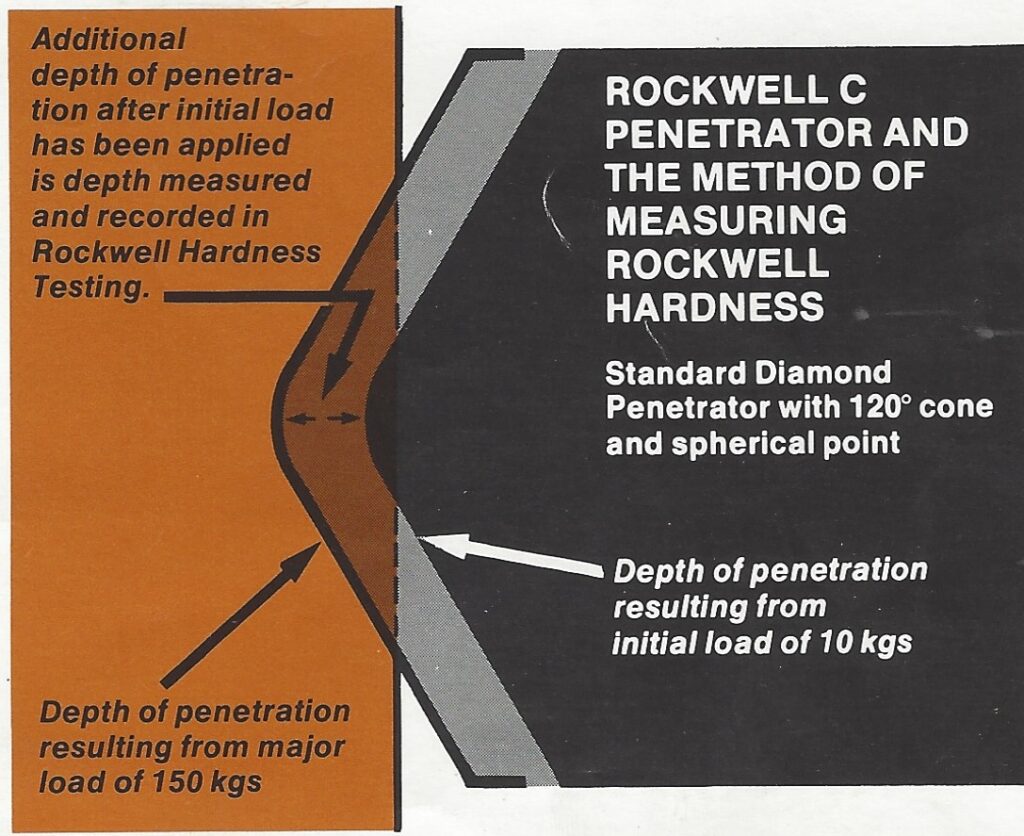

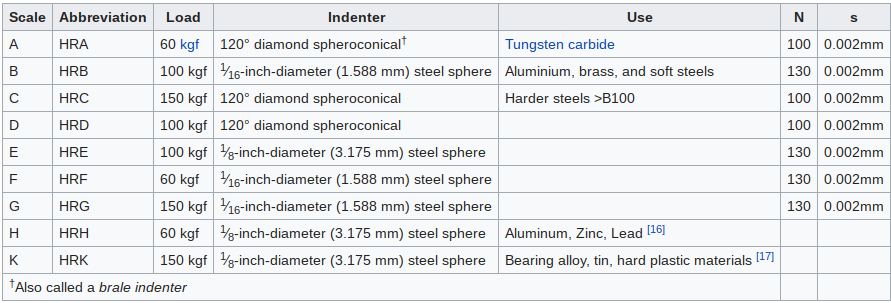

Ames Portable Hardness testers read in the Rockwell scale. The Rockwell scale uses indentation and measures the depth of that indentation with a major and minor load to determine the hardness of a metal. The scale used depends of the metal being tested and the portable hardness tester used.

Ames developed a conversion chart for use in converting Rockwell scale readings into the Brinell scale. This allows you to easily determine the equal Brinnell reading. This conversion chart is broken down into categories to help you determine the converted value.

Hardened Steel and Hard Alloys, locate the type of penetrator you used and the scale you used in the top column for the scale. In this case you will only see C, A, D, 15N, 30N and 45N scales which can then be converted into the Brinell scale. Follow the appropriate line across to locate the corresponding reading in the middle column marked ‘Brinell’.

The next section is Soft Steel, non-ferrous metal, grey and malleable iron casting, this section covers the B, E, F, G, 15T, 30T and 45T scales. You will need to find the appropriate load in order to find the correct conversion. The bottom of this conversion chart includes corrections which cover any readings that were not included in the original chart.

The right-hand side of the chart gives you a guide to choosing the appropriate penetrator and hardness scale for your metal.