Using Ames Testers in Hobby applications

Why Hobbyists Prefer Ames Testers

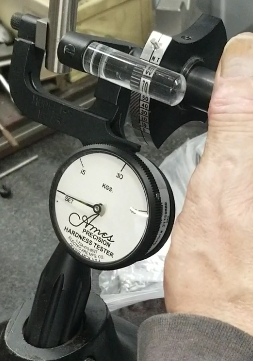

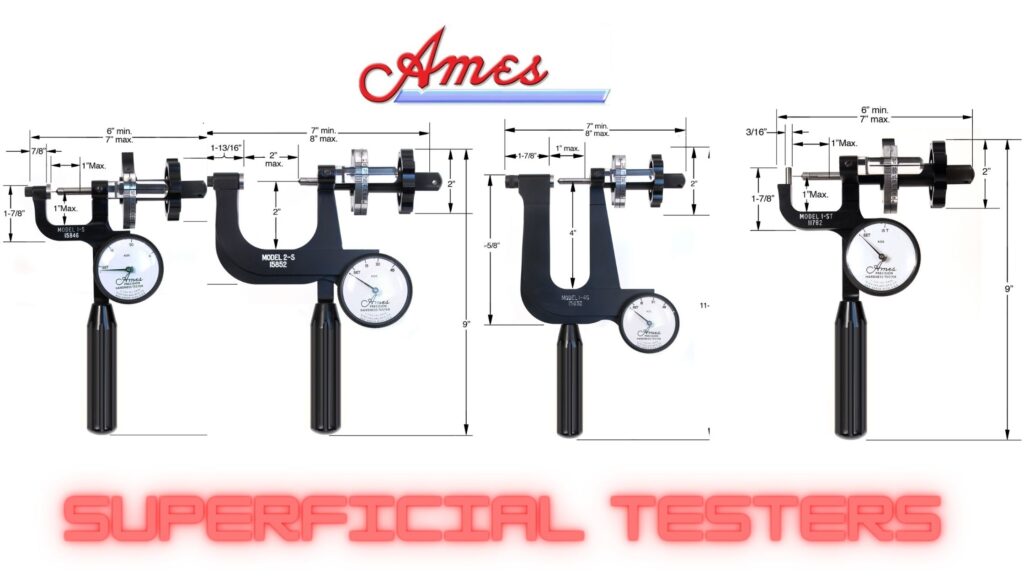

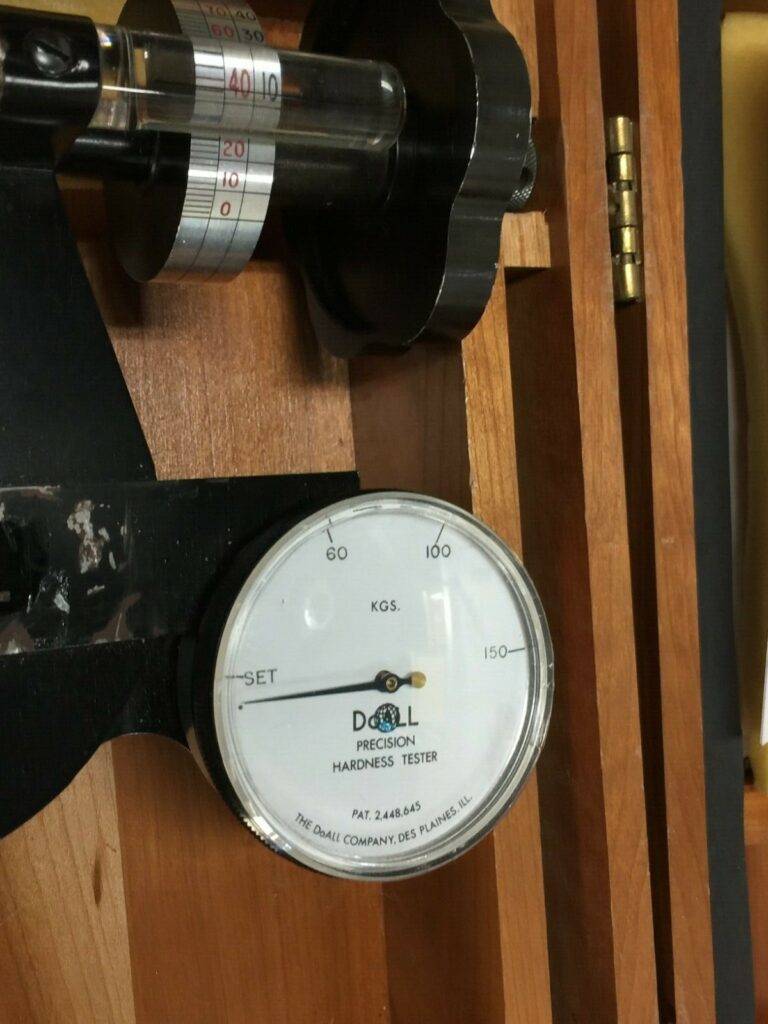

The Ames Portable Hardness Tester is a device used to measure the hardness of metals and alloys. While it is primarily used in industrial settings for quality control and material testing, there are also hobby applications for this tool. As we discussed in a previous blog, Ames portable testers are popular among knife makers. Even the old testers are used because they are looking for a ballpark hardness in their trade.

Forging Martial Arts and Hunting Bladed Tools

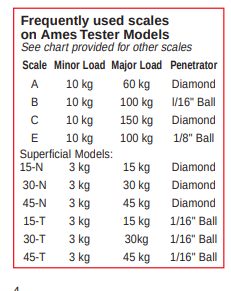

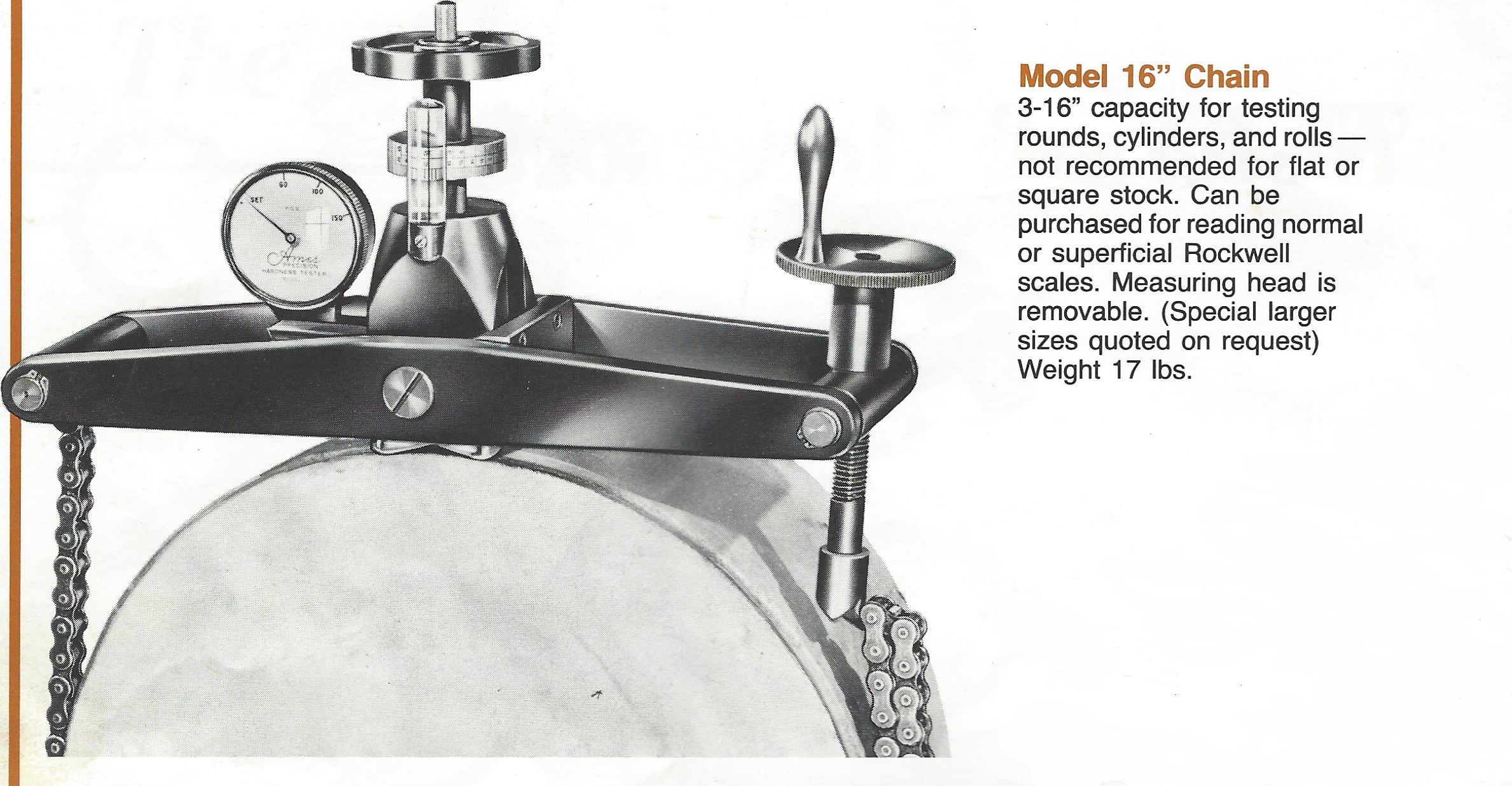

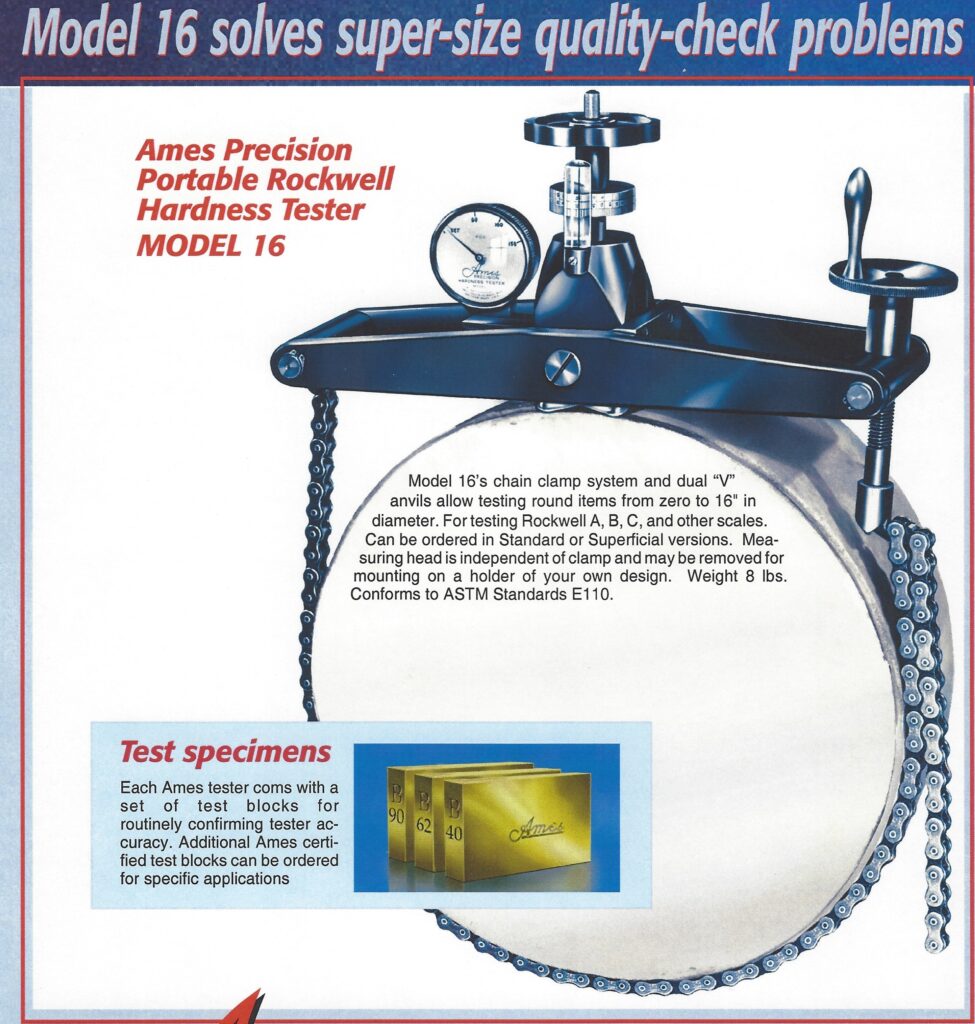

The smithing forums tend to get mentions of Ames portable hardness testers as a reliable tool for the trade. In the Blade Smiths Forum, ‘JenniferP’ ported about her Ames tester, stating it provides more accurate results than the Accu-test HRc tester. Many members commented that they had old testers, but they are no longer eligible for calibration. Just a reminder, we may be able to repair and calibrate your old tester but without certification. The reason for this is the fatigue on the frame makes the instrument unreliable. It may leave our factory calibrated, but arrive to you not testing accurately. While exact results are not always the goal of a Hobby Knifemaker, precision is a promise our company stands by. Accuracy may be a critical point, especially for small thin pieces. As mentioned on BladeMag, the correct hardness will guarantee superior strength in a blade. The hardness test gives you an idea of the flex strength and confirms that the knife’s edge will hold. Although many testers have been used by knife makers, testing with a Rockwell hardness tester provides the most reliable results.

In another forum for Hobby machinists, a member finds an old hardness tester and asks “How can this tool benefit my Hobby” to which other members answer, that this instrument is helpful for anyone heat-treating steel, and another member offers to take it off his hands. Hobby applications in testing clutches for racing led to the development of a specific testing application which was developed outside of normal Ames tester capacity. The Ames tester has value for any hobby application requiring a hardness test.

Some Examples of Hobbies that Ames Tester are Useful with:

-

Metalworking: For hobbyists who enjoy working with metal, the Ames Portable Hardness Tester can be a useful tool for testing the hardness of different metals and alloys. This information can help guide decisions about which materials to use for specific projects, as well as provide a baseline for comparing the hardness of different materials.

-

Jewelry making: In the world of jewelry making, the hardness of metals is an important factor in determining their durability and resistance to wear and tear. The Ames Portable Hardness Tester can be used to measure the hardness of different metals used in jewelry making, such as gold, silver, and platinum.

-

Gunsmithing: For hobbyists who enjoy gunsmithing or working with firearms, the Ames Portable Hardness Tester can be a valuable tool for testing the hardness of gun parts and components. This information can help ensure that the parts are made from high-quality materials and are durable enough to withstand the rigors of use.