5 Benefits of using Ames Portable Rockwell Hardness Testers

Feb 17, 2022

by Ames Portable hardness testers

0 Comments

#Ames portable hardness tester, #Ames portable hardness testing, #Ames rockwell hardness tester, #Ames tester models, #measuring rockwell hardness, #rockwell hardness

Do you wonder if Ames portable hardness testers are the best option for you to use when testing the hardness of metal? Here are 5 reasons to choose Ames when you choose your hardness tester.

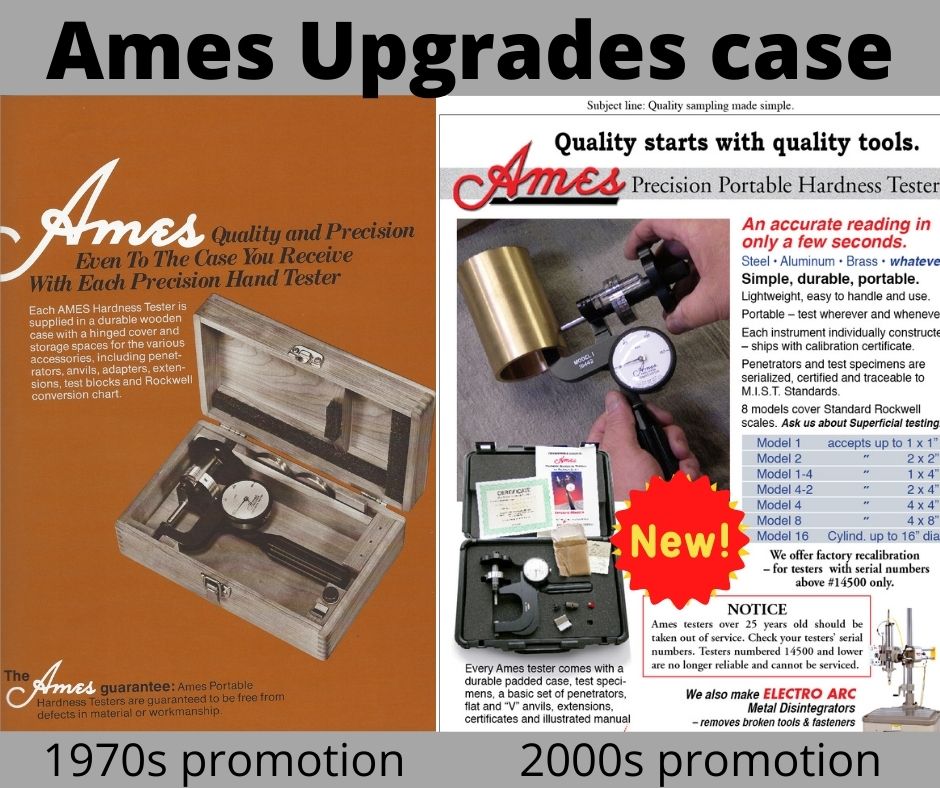

- Ames provides you with repeatable accuracy. Repetative tests on the material will give you in the same reading. You may not find this benefit generally available on competing hardness testers. You will experience no loss of accuracy when you transfer your readings into Rockwell scales. This is because all readings are made directly into Rockwell scales. Ames tester accuracy may be compared to the accuracy of bench-type testers when you perform tests in the smae enviornment.

- Ames hardness testers are simple for you to operate. Even unskilled users can learn to make accurate tests after a very limited period of practice. This means you do not need highly qualified inspectors to make hardness tests. This allows you to perform hardness testes more frequently, and provide your customers with maintenance and closer tolerances for their products.

- Portable testers can be taken anywhere. With hardness testers that are not confiened to the labratory you can perform hardness tests on material at the assembly line, in the receiving yard, or on material still assembled in the machine. You will avoid delays in production. You can also perform hardness tests in scenerios that are not accessable for use with bench style hardness testers.

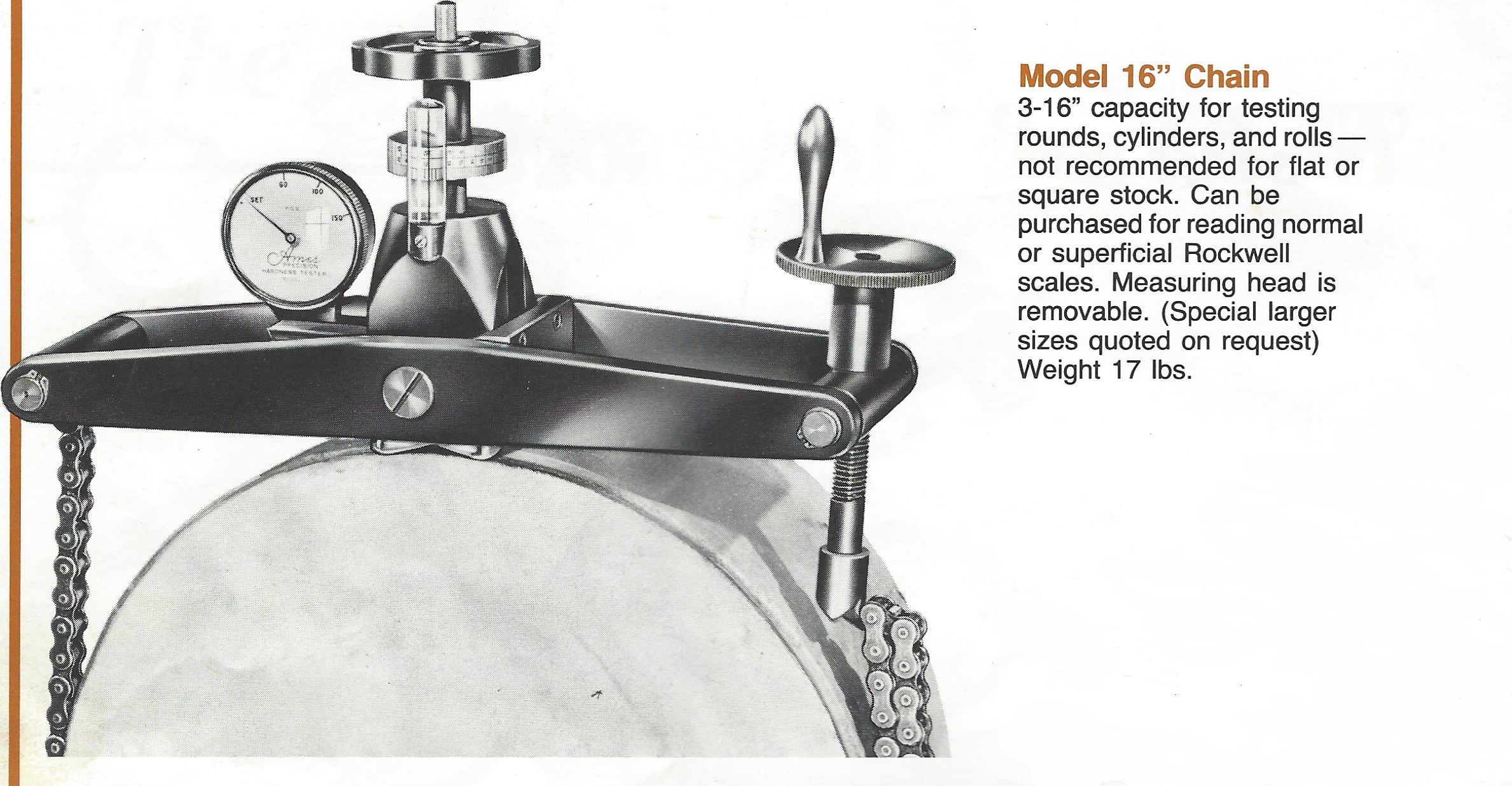

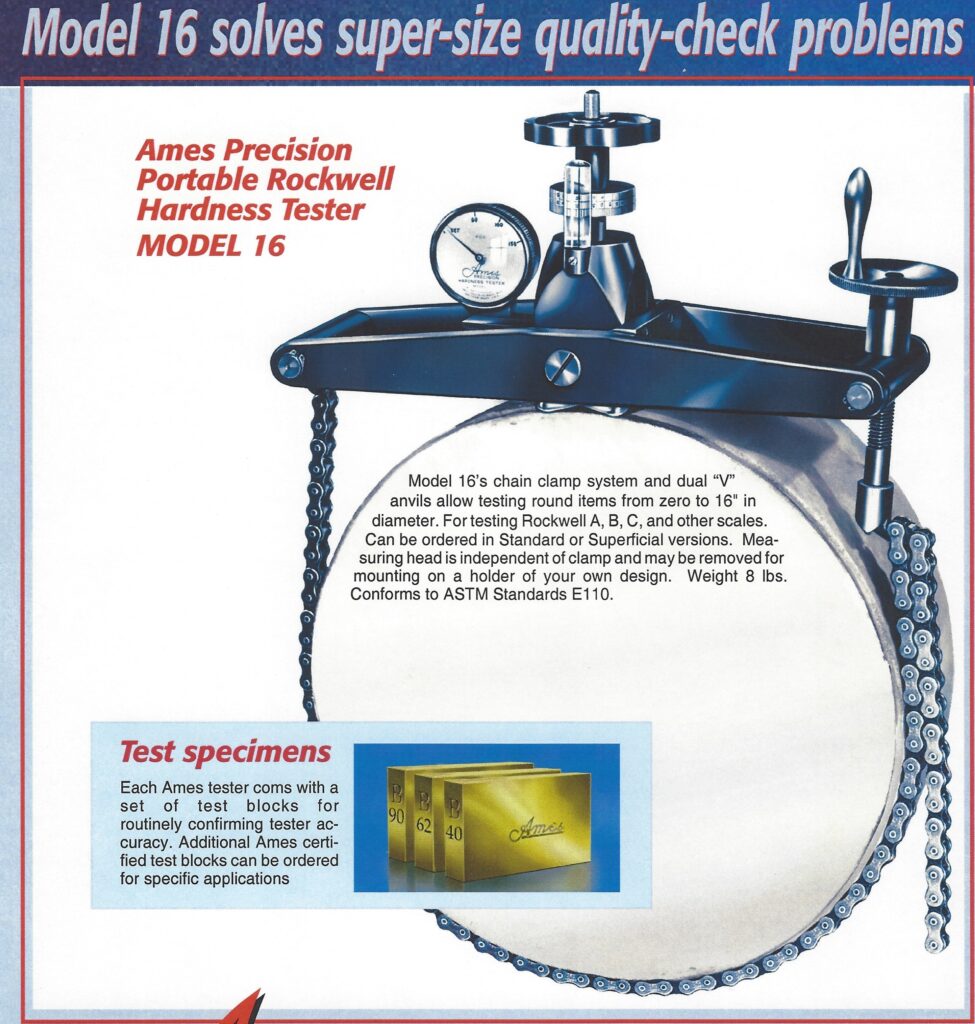

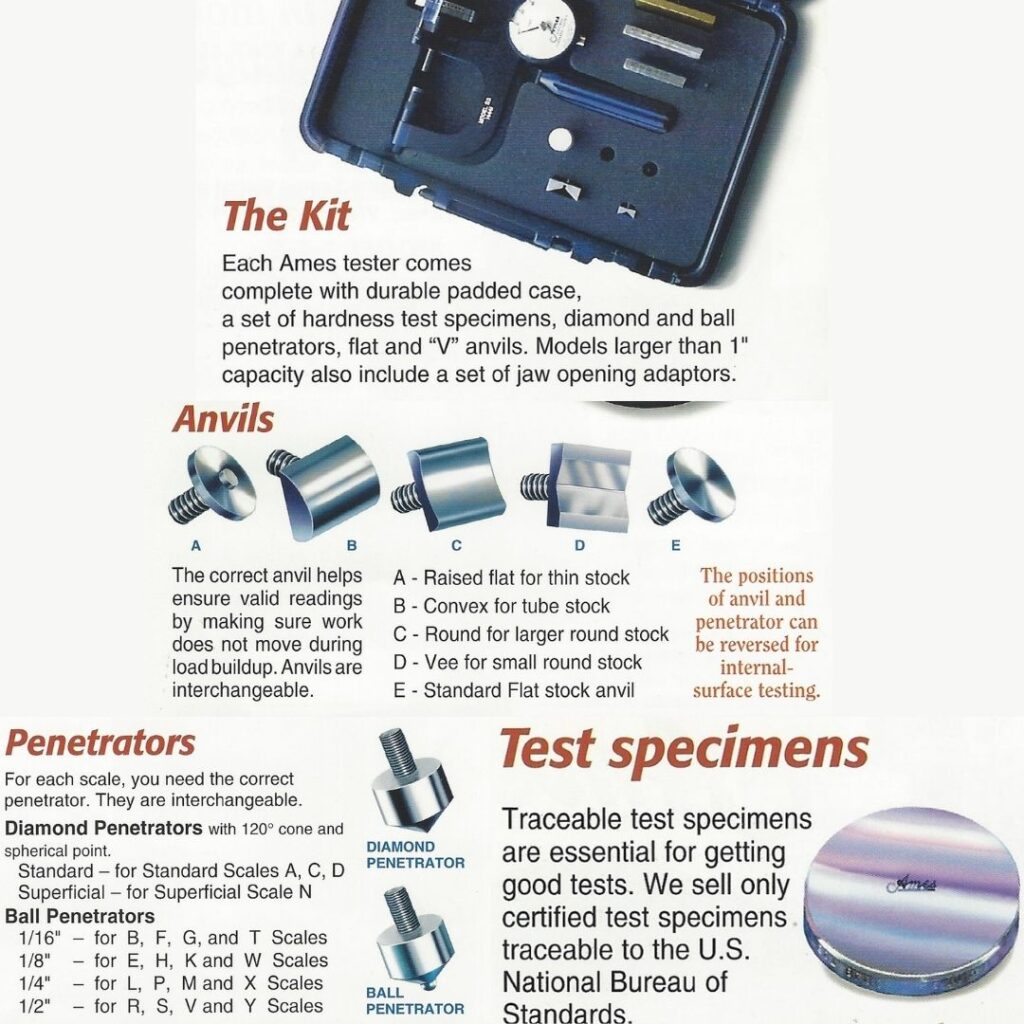

- Test in Rockwell A, B, and C. Ames portable hardness testers allow you to test directly in regular Rockwell A, B and C scales, or in Rockwell Superficial N and T scales. You can simply change the penetrator and the major load and your tests can be made in Rockwell D, E, F, G, H, K, L, M, P, R, S and V scales. You can refer to the following conversion chart for Rockwell Hardness. Ames’ extensive line of portable hardness testers allows you to test material in a size range of 1mm to 1 meter in diameter.