What Comes with a New Ames Portable Hardness Tester?

A Look at the Ames Portable Hardness Tester Kit

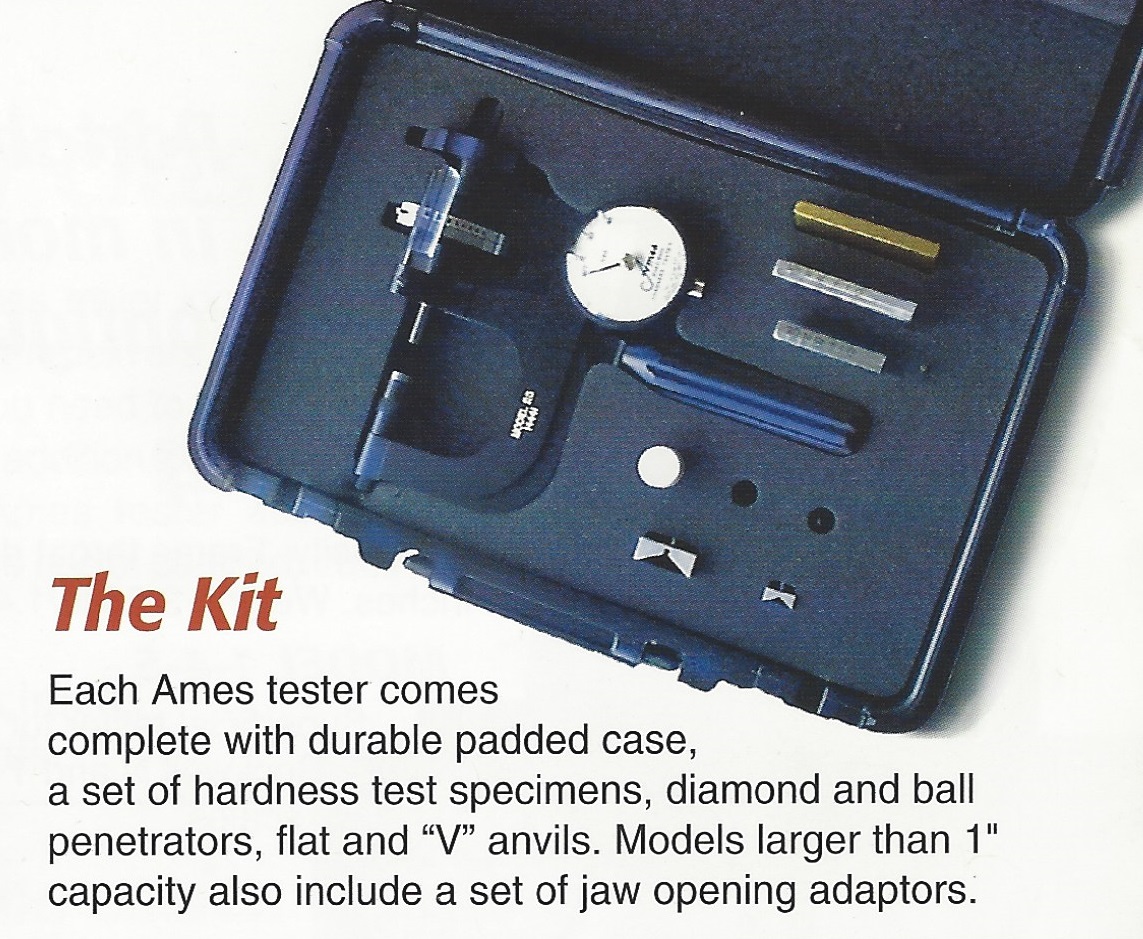

The Ames Portable Hardness Tester case is made from high impact plastic, lined with foam to keep your Ames Portable Hardness Tester safe in transit. There is a space for your Ames Portable Hardness Tester, 3 test blocks, penetrators and anvils in this case. You may also choose to purchase one of Ames limited edition Model 1 testers in the original wood box. This is a new tester in the old style box which was discontinued.

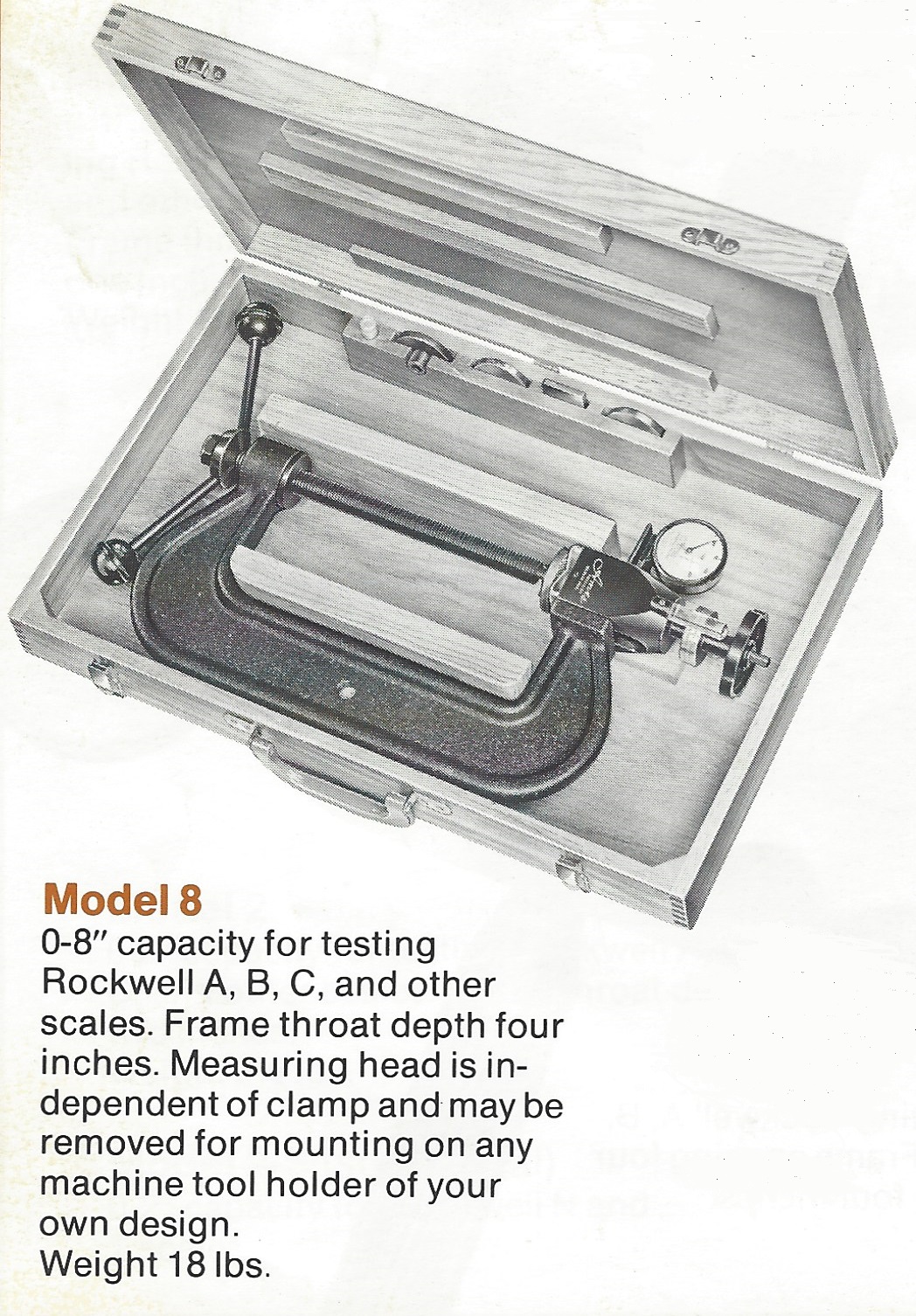

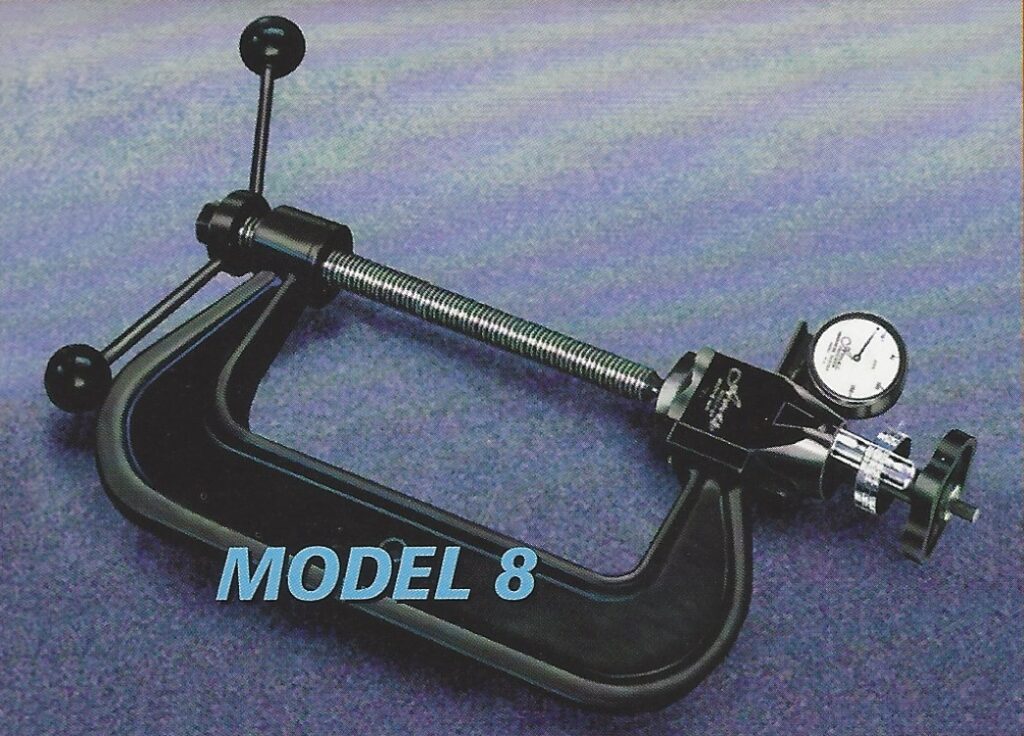

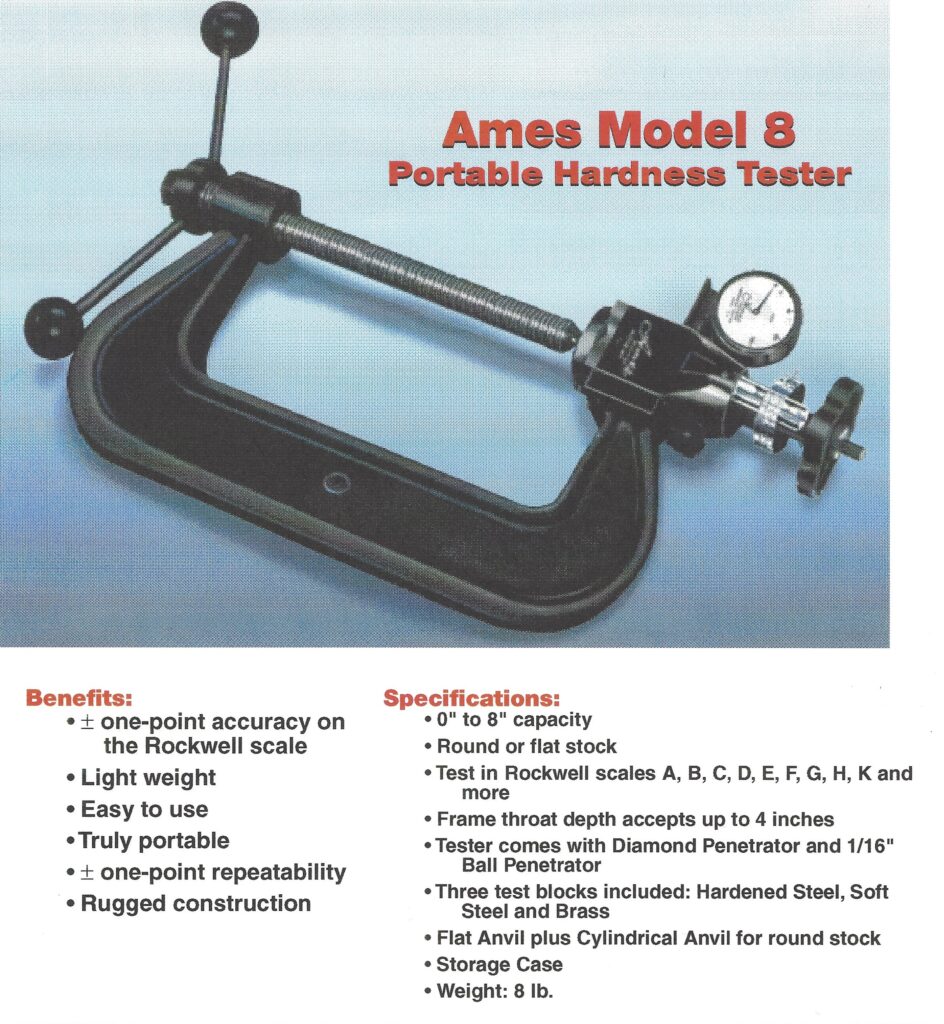

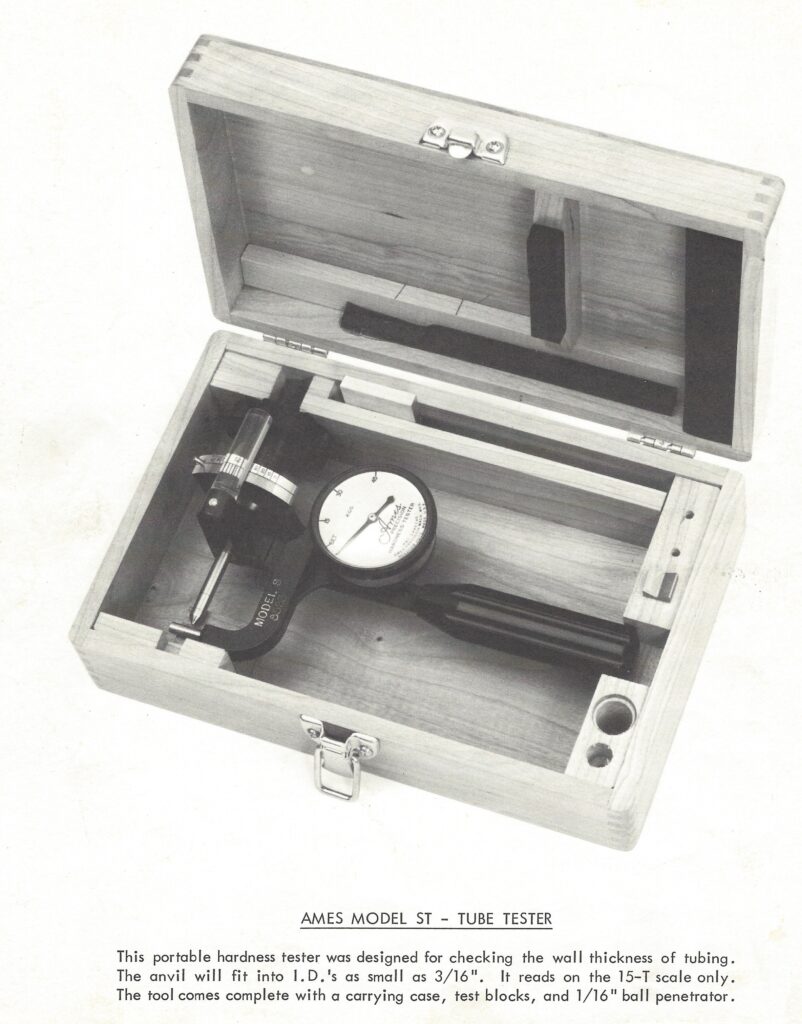

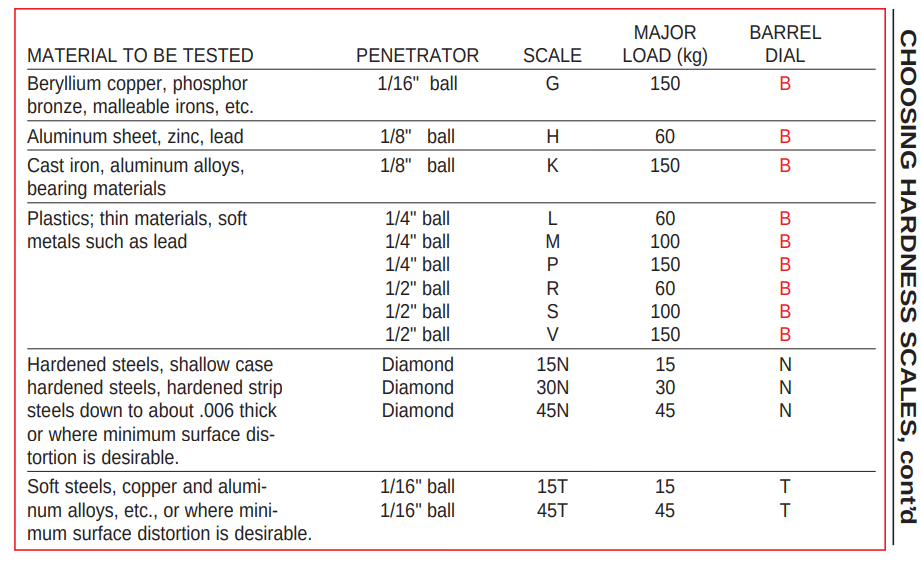

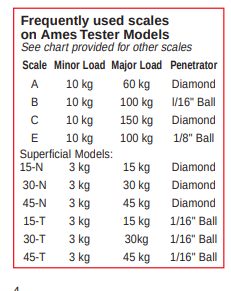

Of course your Ames kit will include the Ames Portable hardness Tester you have selected. We manufacture Standard hardness testers which include the Model 1, Model 2, Model 1-4, Model 4-2, Model 4-4, Model 8 and Model 16 which test in Rockwell A, B, C, D and F scales, if you use them with our optional ball penetrators, they also test in Rockwell E, H, L, M, R, S and V scales as well. Our Superficial hardness testers include Model 1-S, Model 1-ST, Model 1-4S, and Model 4-2S which read in Rockwell scales N and T. Using the additional ball penetrator they can also read in W, X and Y scales with the exception of the Model 1-ST which only reads in 15-T for tube testing. The only tester that does not include a carrying case is the model 16.

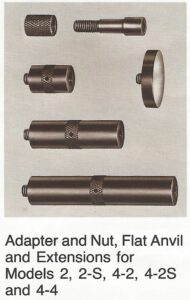

Your kit will include a flat and a “V”anvil. Anvils aid you in ensuring your tester provides valid readings. The standard flat stock anvil is our most used anvil as it is designed for use with flat stock. The “V” anvil is for small, round stock. Anvils are interchangeable. We also sell raised flat anvils for thin stock, convex anvils for tube stock, round anvils for larger round stock.

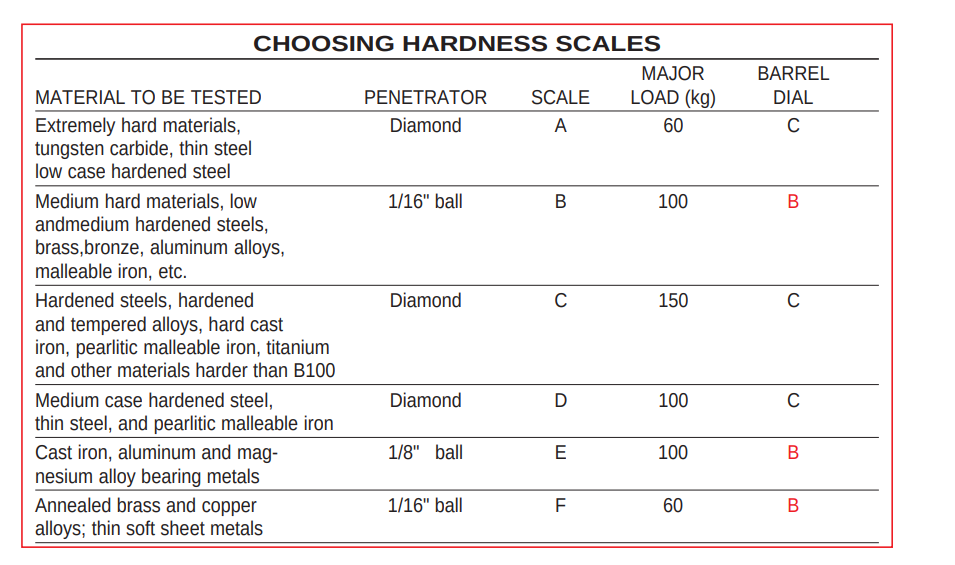

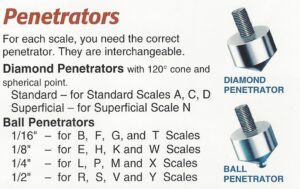

You will receive one diamond penetrator and one ball penetrator in your Ames Portable Hardness Tester kit. These penetrators are interchangeable. You will need a different penetrator depending on the scale you are testing in. Diamond penetrators are necessary for harder metals. You can always purchase replacements on our website.

You will receive one hard steel, one soft steel and one brass test block with your Ames Portable Hardness Tester kit. These testers help you with accuracy testing to ensure your tester is reading correctly. Each Ames test block includes a certificate of calibration. Superficial test blocks are standard with our superficial testers, and standard test blocks come with our standard hardness testers. You may special order test blocks as well.

Ames hardness tester kits come standard with two extensions, one 1″ and one 1/2″ extension.

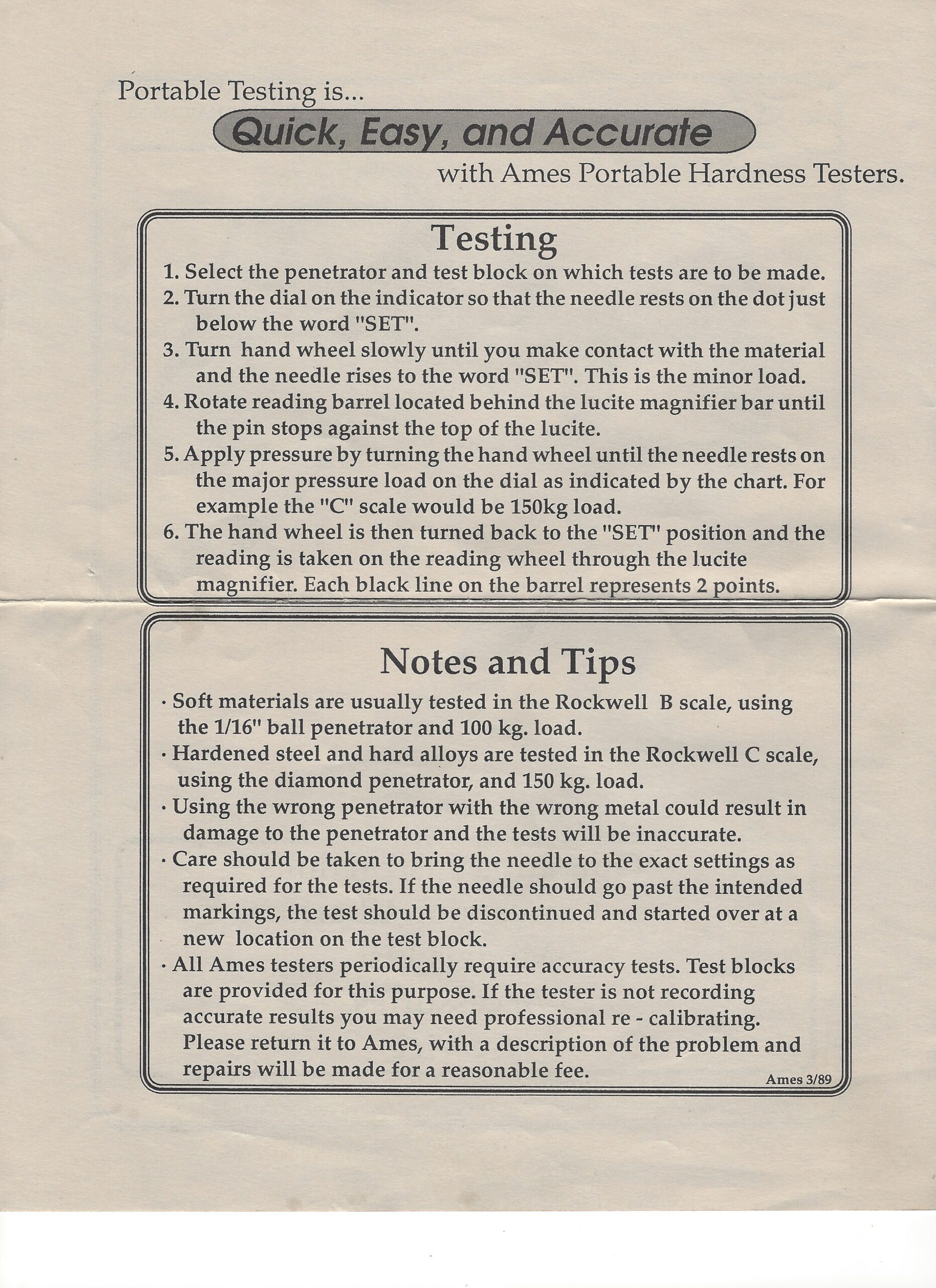

Each Ames Portable Hardness tester includes a manual for use of your hardness tester. If you lose your manual or need another copy, you can download it from our website at any time. It is important to review this manual for proper care of your hardness tester, it also includes conversion charts for your use.

Every Ames tester is factory calibrated before it is sold and every tester comes with a certification of calibration, our Ames test blocks include certification to the hardness on the test block. Our testers meet NIST and ASTM E-110 standards. You should return your tester to our factory for calibration once a year to ensure it continues to read accurately. We also offer repair services.