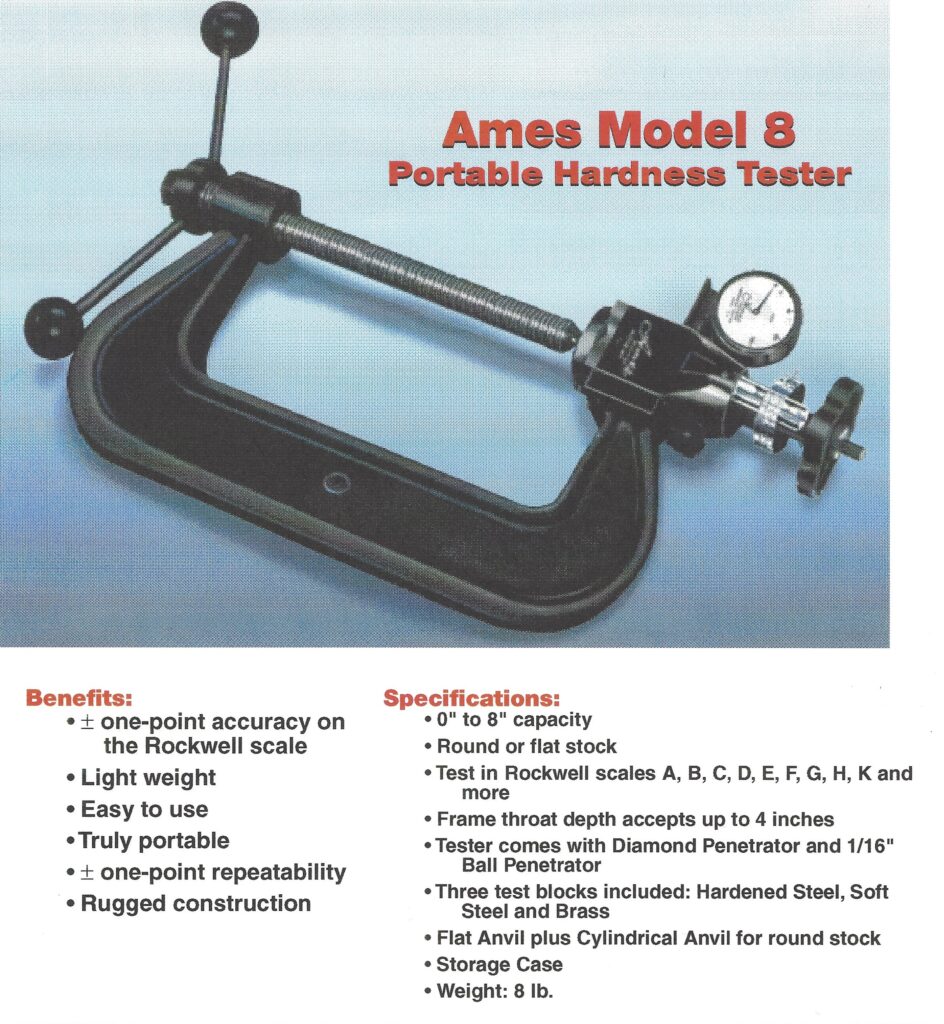

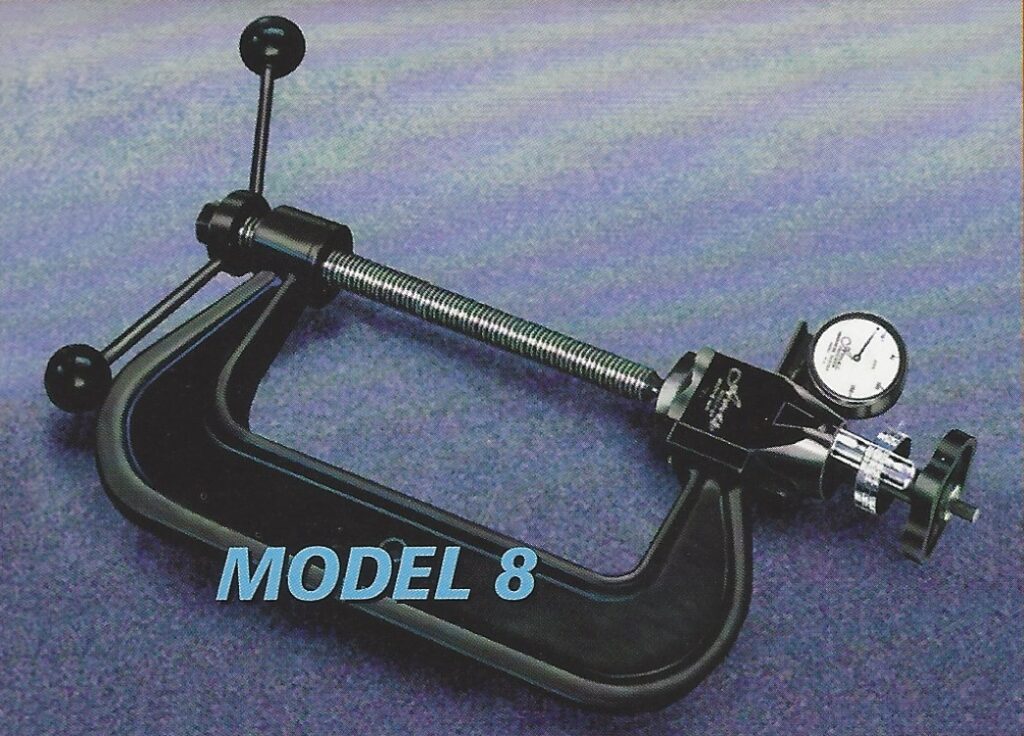

Ames Announced the Model 8 Portable Hardness Tester in 1975

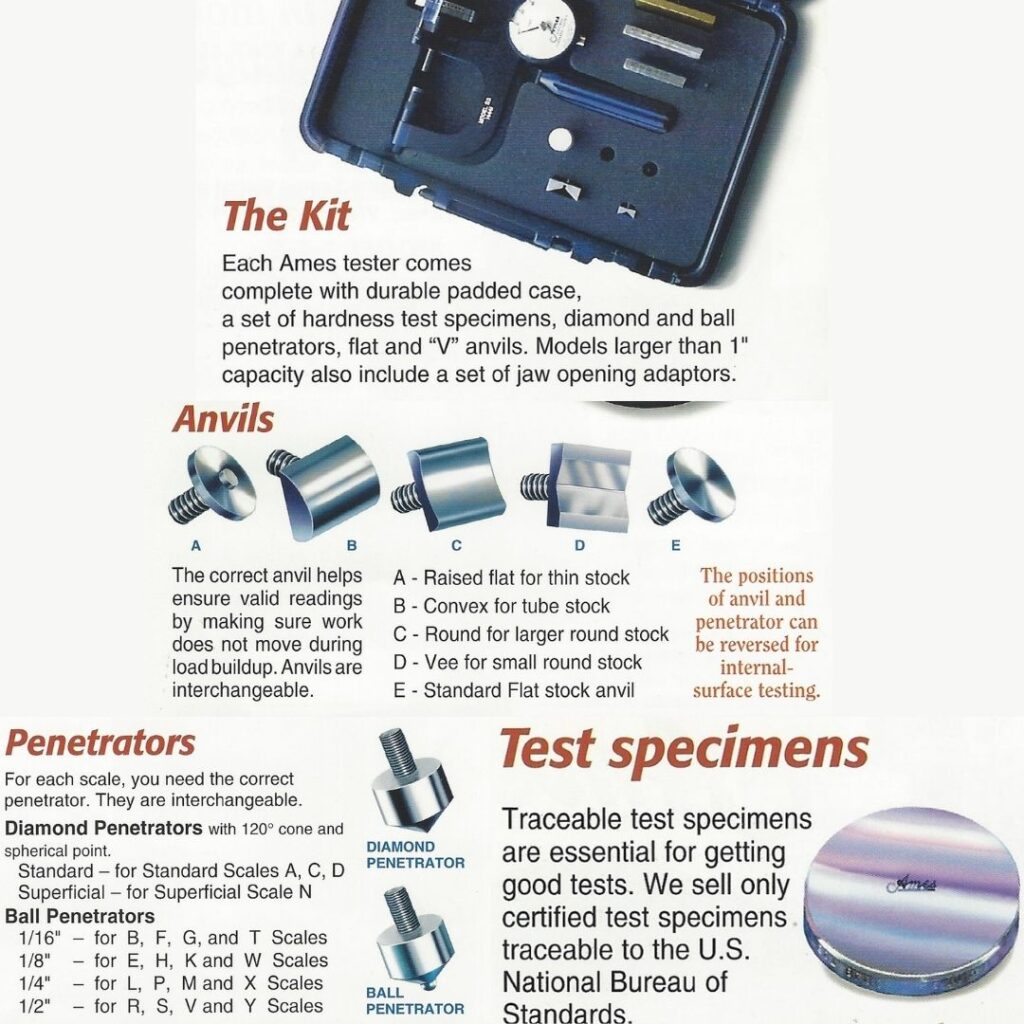

Ames introduced the model 8 hardness tester in February of 1975. This portable hardness tester has the capacity for either rounds or flats up to 8 inches to determine the hardness of metals and alloys in various Rockwell scales.

See the Model 8 Hardness Tester in Action!

The model 8 Ames portable Hardness Tester saves time and money by its ability to be taken to the workpiece being tested rather than having to cut pieces off to be taken to the laboratory for testing. The measuring head is independent of the measuring clamp or machine tool holder of your own design.

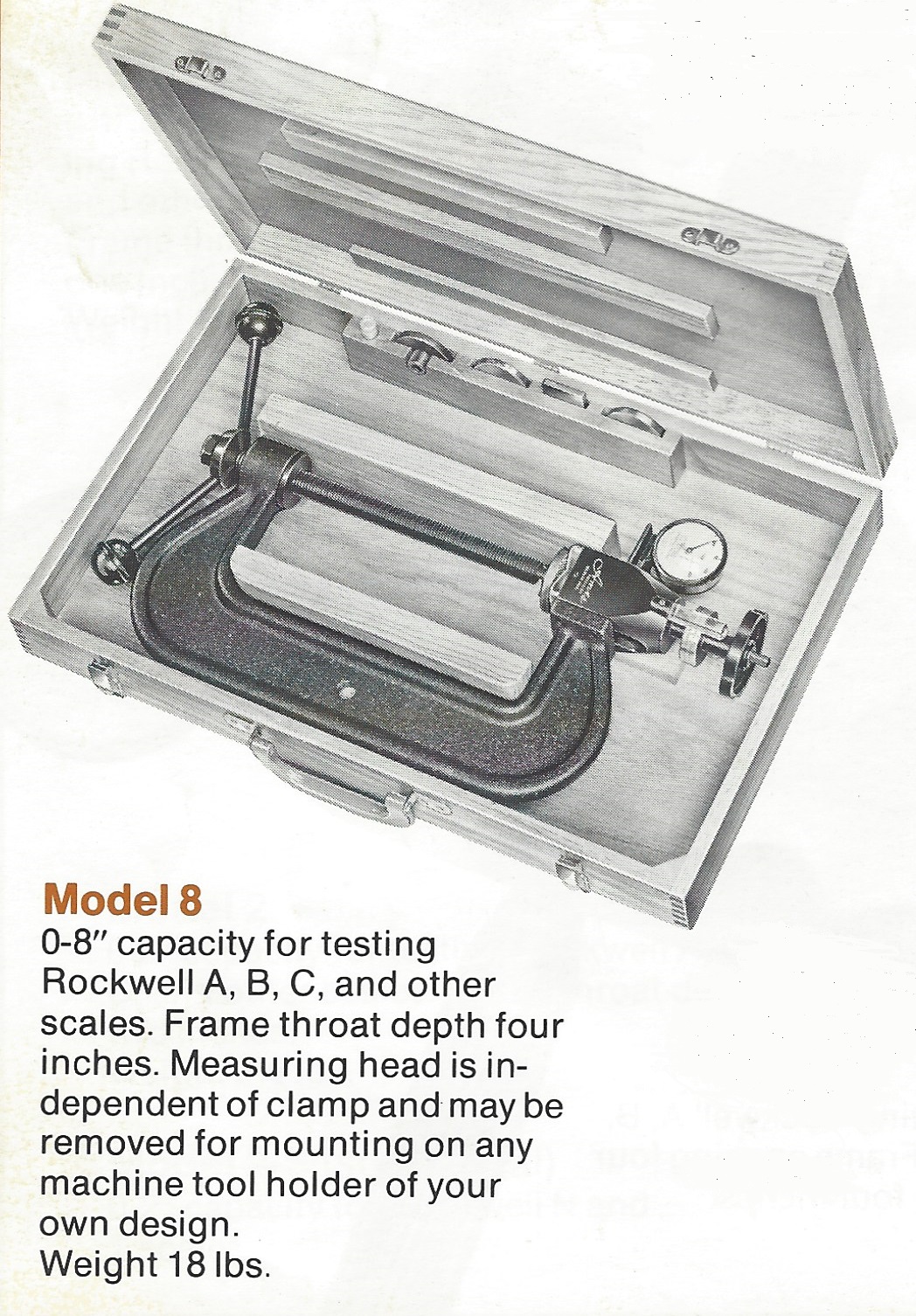

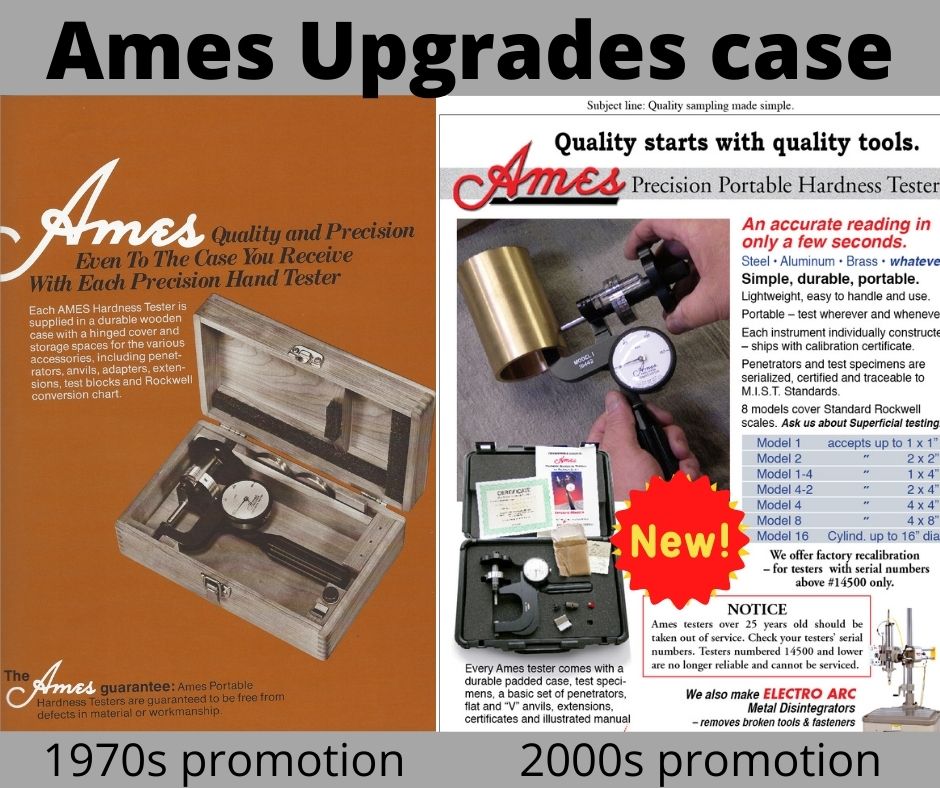

The model 8 Ames Portable Hardness Tester is accurate, light to carry, and easy to use. This tester meets the needs of both large and small plants. Use model 8 to test standard Rockwell scales, this tester is convienently is supplied with a carrying case.

With a frame depth of 4 inches, this tester reads Rockwell A, B, C, and other scales. The measuring head may be removed and mounted on a tool holder. This tester weighs 8.25 pounds.