Rockwell Hardness Charts for Metals

Ames Rockwell-Brinnell Conversion Chart

Our handy conversion chart helps you convert your Ames Hardness Readings from the Rockwell scales to Brinnell scales

Download NowChoosing a Rockwell Hardness Scale

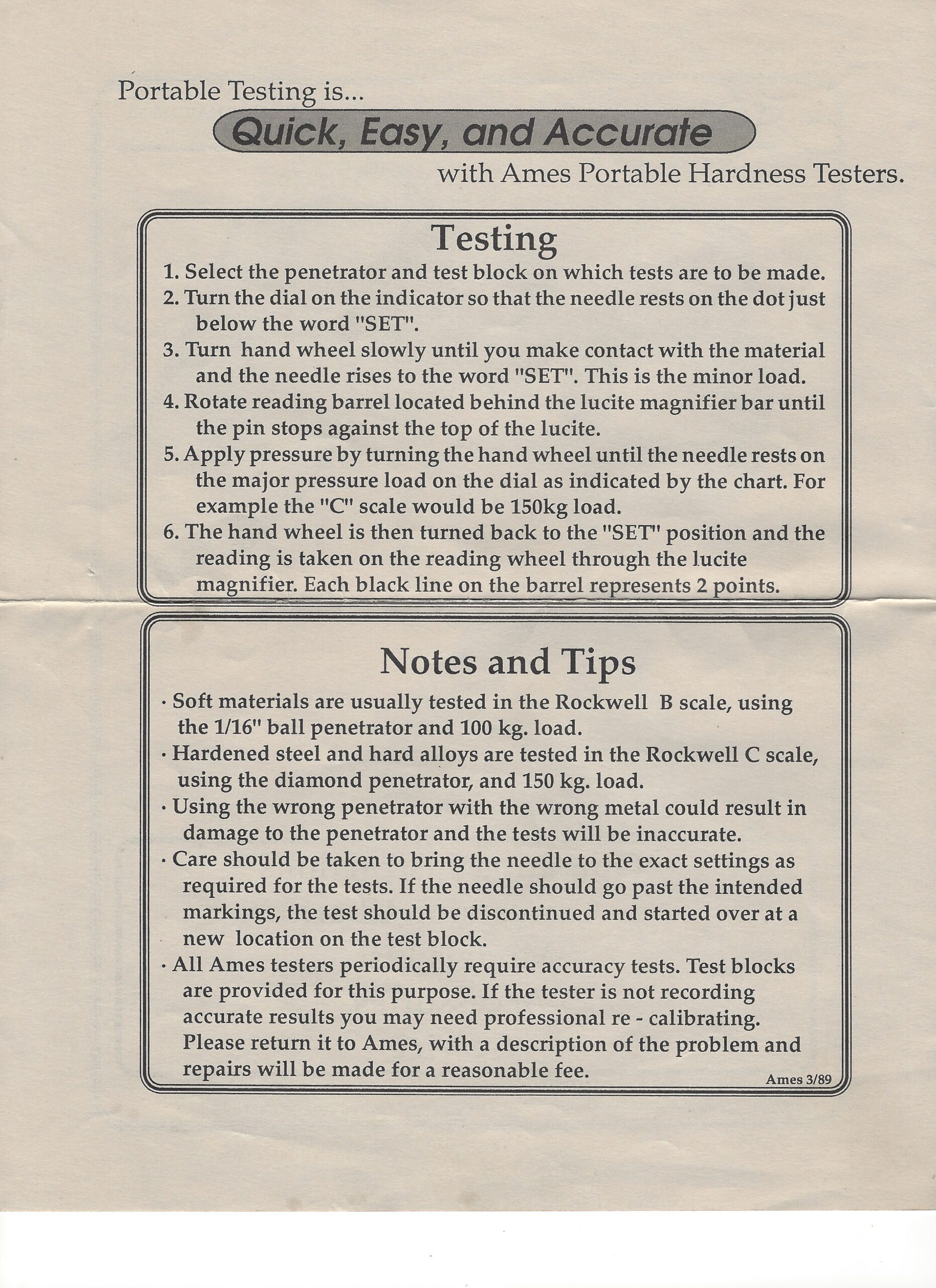

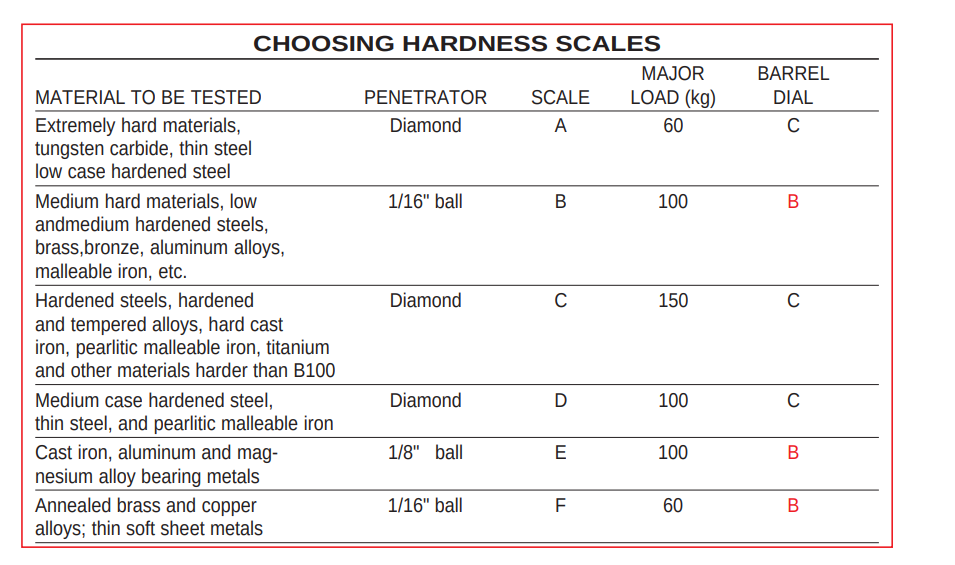

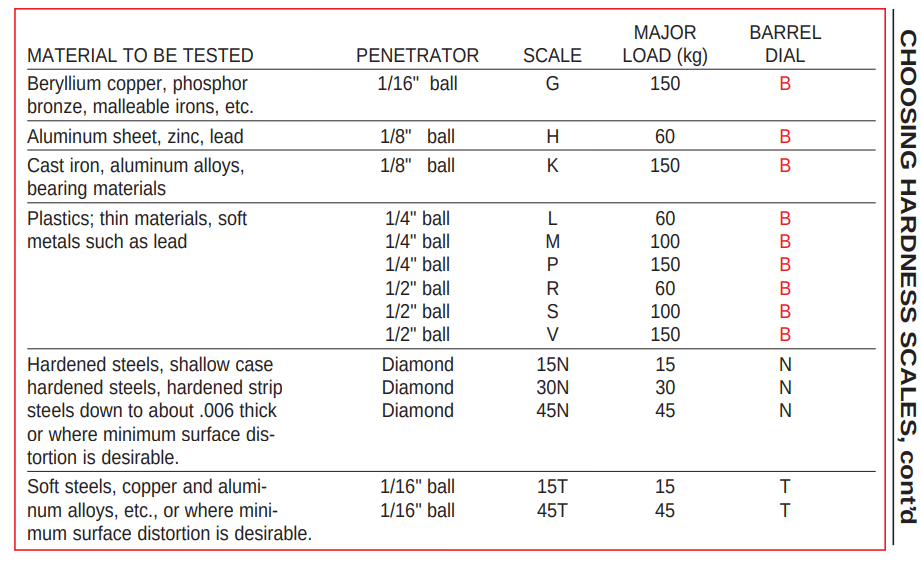

Below are a few Hardness Scale charts that will help you choose the proper set up for your Ames Rockwell portable hardness tester. The charts cover the following :

All information included in this article is found in the Ames Tester Manual. Download it here.

Material to be tested –

Very hard metals, soft and hard steel, aluminum, brass, and thinner materials can all be tested with our testers.

Brass and aluminum alloys can be handled by using a 1/16 ball

The penetrator that is needed –

Very hard metals like tungsten carbide, and thin steel needs to be tested using a Diamond penetrator.

Brass and aluminum alloys can be handled by using a 1/16 ball

Brass and aluminum alloys can be handled by using a 1/16 ball

The major load to be applied –

Your tester is guaranteed to +/- 1 point Rockwell. When using this tester, you must use extreme care to position the pointer exactly on the minor and major load marks.

Lastly, the correct Barrel dial setting –

The upper line of the barrel’s hardness scales should be exactly aligned beneath the hairline on the magnifier.

Do you need to convert Brinell to Rockwell? See our Rockwell/Brinell conversion chart.

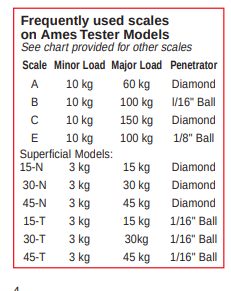

Here are some commonly used scales on our models.

Please contact us with any questions regarding proper maintenance and set up of our Rockwell testers.