When to Choose an Ames Superficial Hardness Tester

There are two types of Rockwell testing:

Standard Rockwell: the minor load is 10 kilograms of force (kgf) and the major load is 60, 100 or 150 kg.

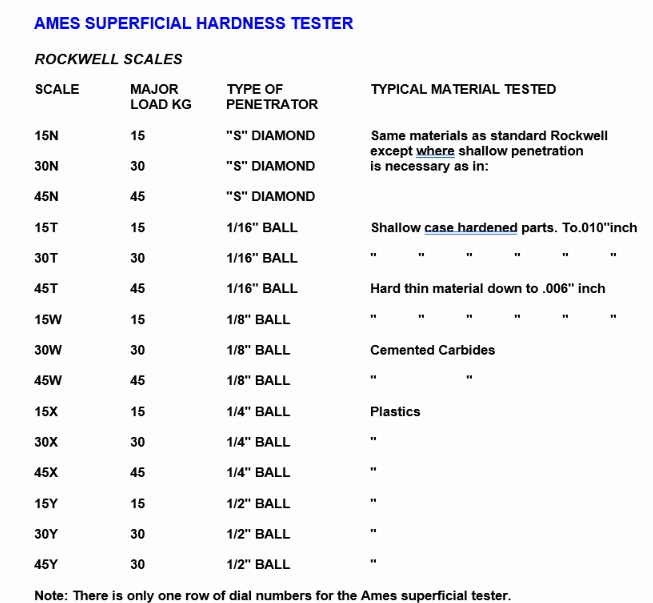

Superficial Rockwell: the minor load is 3 kg and the major load is 15, 30, or 45 kg.

In conducting both tests, you nay use either a diamond cone or steel ball indenter, depending on the characteristics of the material you are testing. Today you will learn more about why you would need superficial Rockwell hardness testing.

The Superficial Rockwell Scales:

Are you wondering when to purchase a superficial hardness tester rather than the standard one? Rockwell superficial scales are used to test materials too thin or small for the regular scales or outside the regular ranges. Generally, Diamond Indenters are used for hard materials while Ball Indenters are used for soft materials. The HR 15 N scale is useful for testing hard thermal spray coatings like ceramics and carbides, while at the other extreme the HR 15 Y scale is used to test very soft abradable coatings Superficial hardness testers can be used for testing shallow areas that you would normally use a standard hardness tester for.

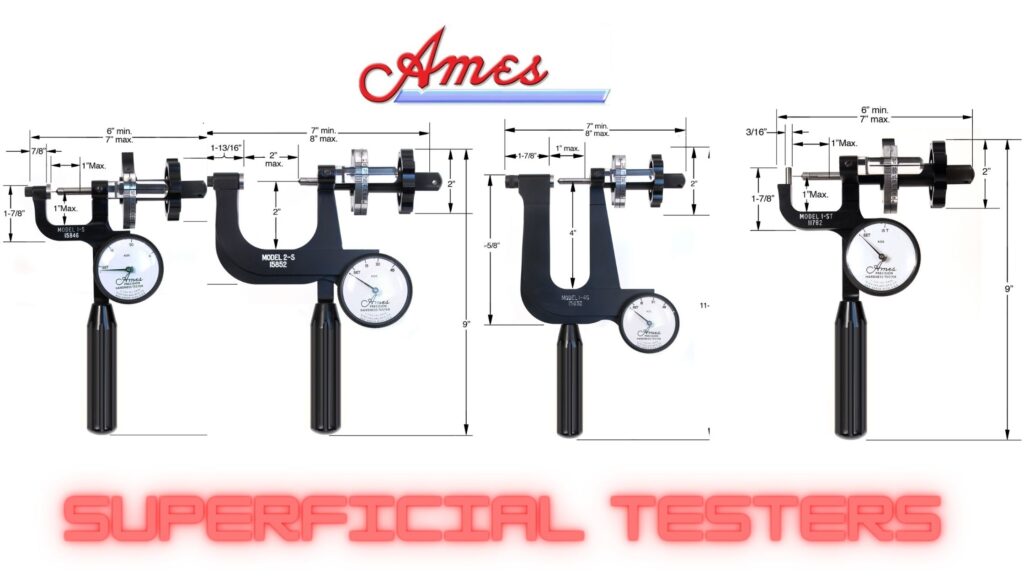

Use a superficial tester when you are testing super thin material that would be damaged by a standard tester’s penetrator, for example, case-hardened steel and shim stock. Battery cases are another example, plastics can also be tested with a superficial hardness tester. The video below gives you a comparison of thin materials and Ames superficial testers you can choose from to conduct a superficial hardness test.

Use Superficial Hardness Testers to Test Thin Materials:

Our special superficial tester is the model 1-ST, this tester allows you to test the hardness of tubes. Tube testing is possible with either standard or superficial hardness testers but the model 1-ST allows you to test very small diameter tubes that are too large to test with the other testers.

Ames Model 1-S Superficial Portable

Metal Portable Rockwell Hardness Testers For Sale Includes: High impact case Diamond Penetrator – Serialized and Traceable 1/16 Ball Penetrator

Ames Portable superficial Hardness Tester

Portable Metal Rockwell Hardness Tester For Sale Includes: High impact case Diamond Penetrator – Serialized and Traceable 1/16 Ball Penetrator

Ames Superficial Portable Hardness Tester

Rockwell Hardness Testers For Sale Includes: High impact case Diamond Penetrator – Serialized and Traceable 1/16 Ball Penetrator – Serialized

Ames Portable Superficial Hardness Tester

Includes: High impact case Ball Penetrator – Serialized and Traceable 1/16 Ball Penetrator – Serialized and Traceable 1 Certified Brass Test

Ames Model 4-2S Portable Hardness

Ames Portable Metal Hardness Testers Includes: High impact case Diamond Penetrator - Serialized and Traceable 1/16" Ball Penetrator – Serialized