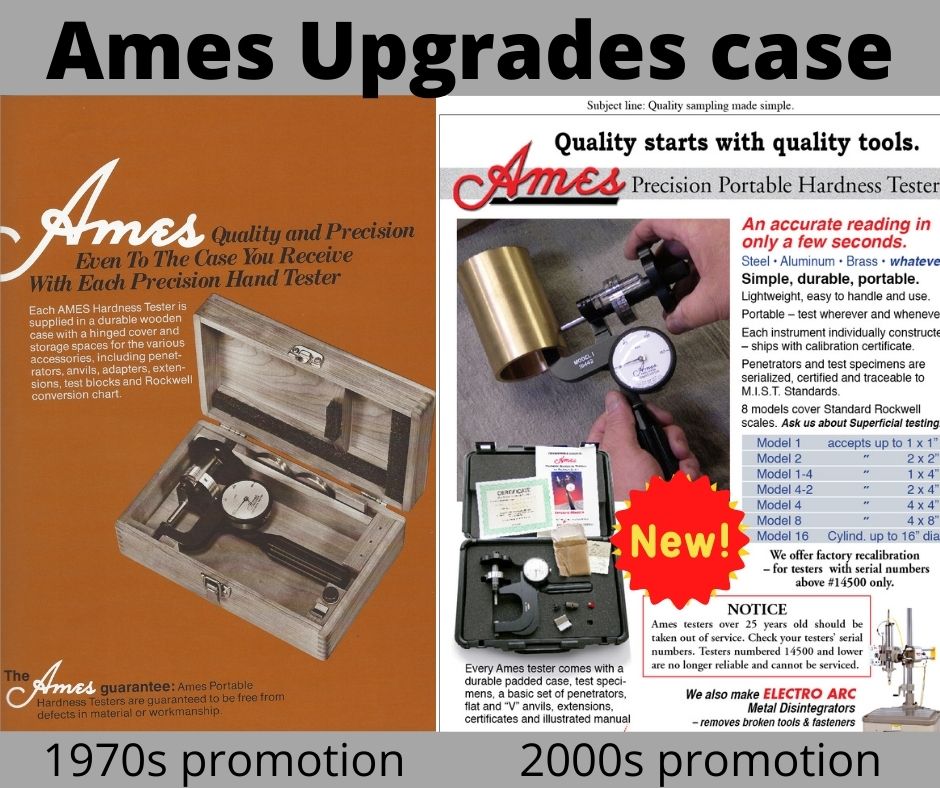

Ames Upgraded their Wooden Instrument Case in 2000

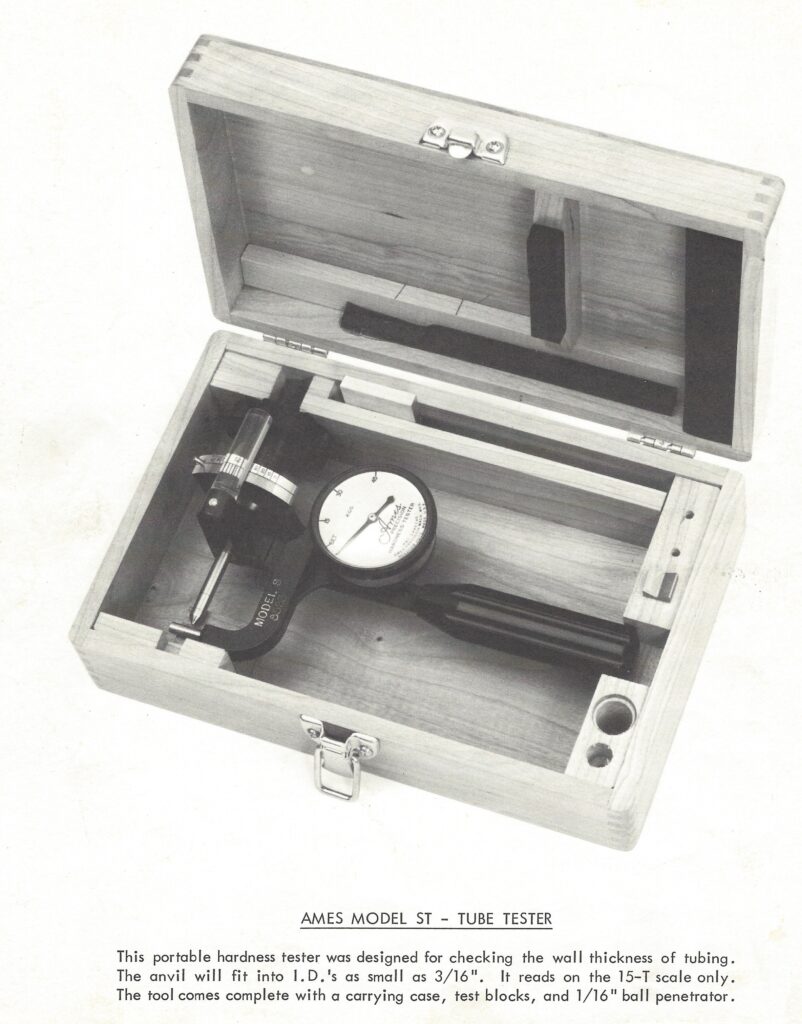

Limited Edition model 1 Portable Hardness Tester in Vintage Wood Case

Enjoy all of the perks of owning an Ames Model 1 Portable Hardness Tester with the Antique look of a wood case! These limited edition Hardness testers are available while supplies last as a celebration for Electro Arc’s 75th Anniversary!

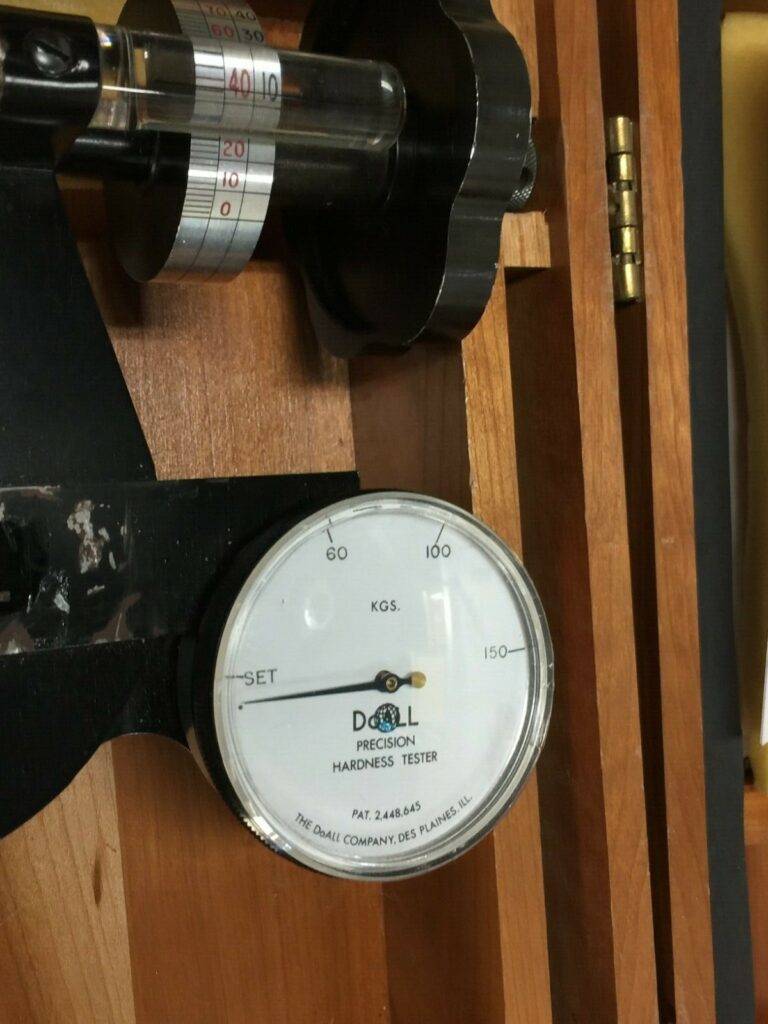

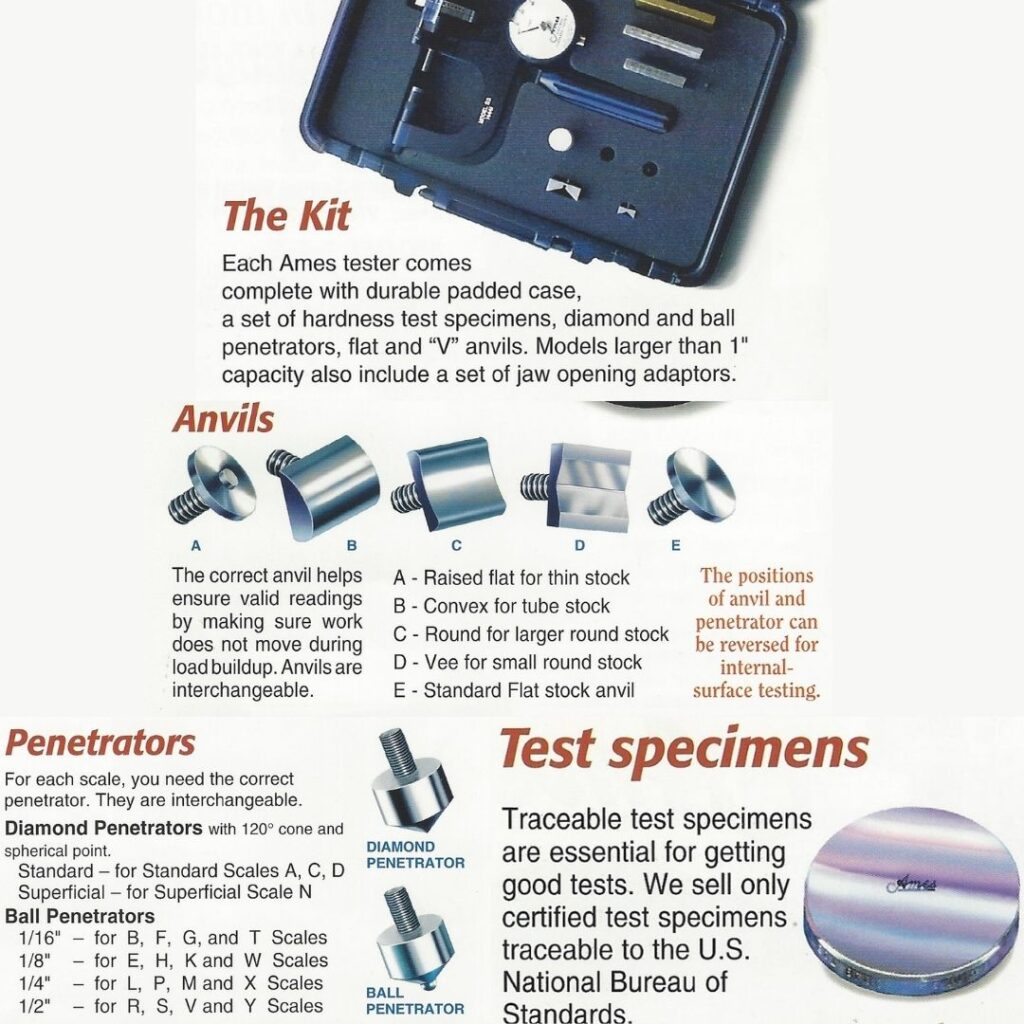

What you get when you purchase an Ames Hardness Tester has never changed, the case you get your tester in did. From the time Electro Arc purchased Ames Portable Hardness Testers in 1975, they were sold as a kit including the tester, a set of hardness test specimens, diamond and ball penetrators, and flat and “V” anvils. Models larger than 1″ also include a set of jaw-opening adapters.

Ames portable hardness testers have a very traditional, fine-instrument look to them. They should: they have been around manufacturing and metal shops for fifty years, quietly doing their jobs. In their highly varnished, dovetail-joined wooden cases, some of them have probably been mistaken for antiques. Ames announced sleek new cases for its proven line of portable, easy-to-use hardness testers in May of 2000. The smart black bolded high impact cases, with full loam cradling provide better protection for these precision instruments than the wooden cases previously supplied.

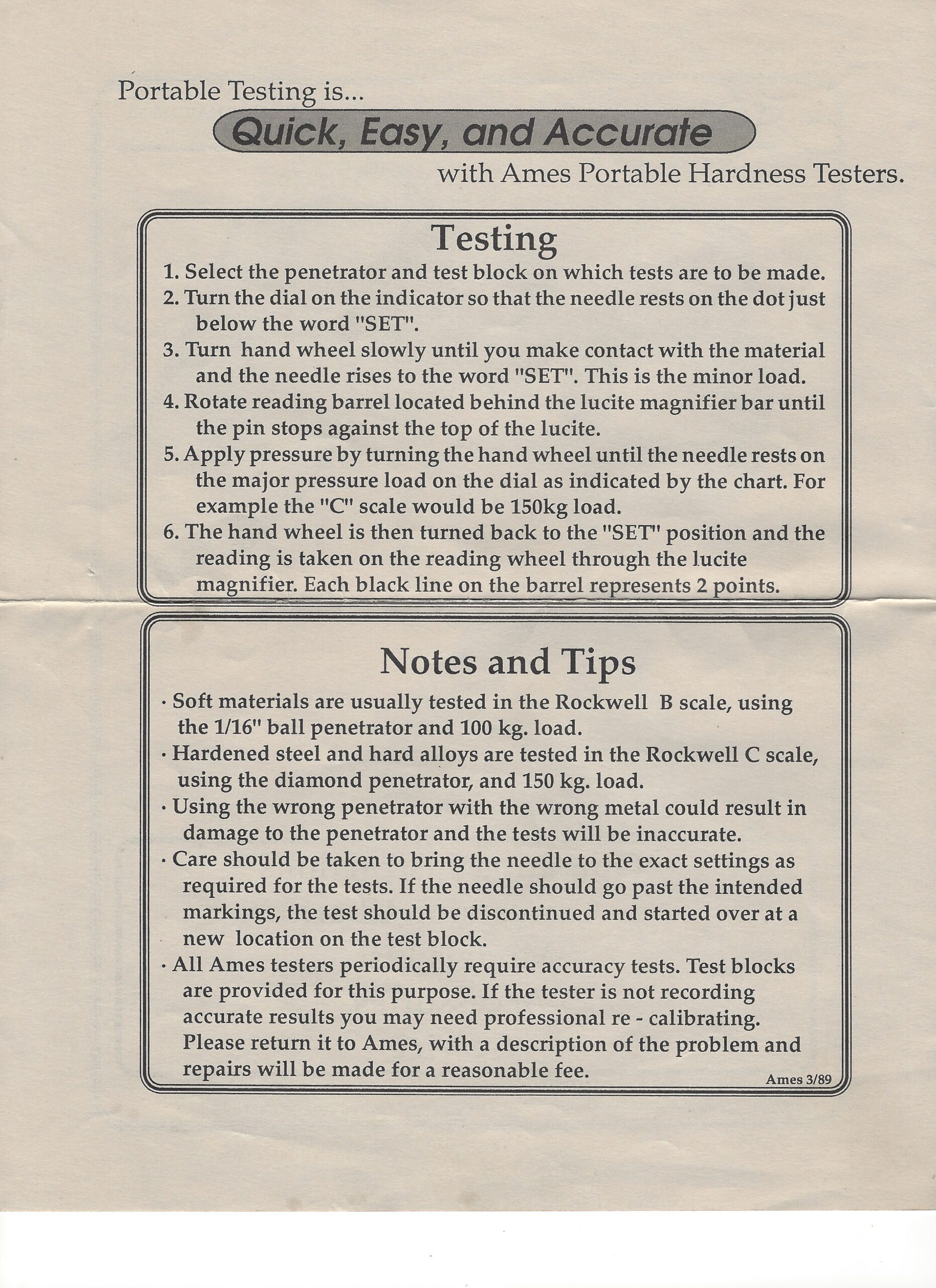

Although they are precision instruments and should be handled as such, they are surprisingly durable. Some Ames testers are still working perfectly after thirty years of service, an age at which other machines really are antiques. Accuracy testing and annual calibration are required to keep these testers testing accurately. To help Ames owners get the most value from their investment, we offer both calibration and repair services for your Ames tester.

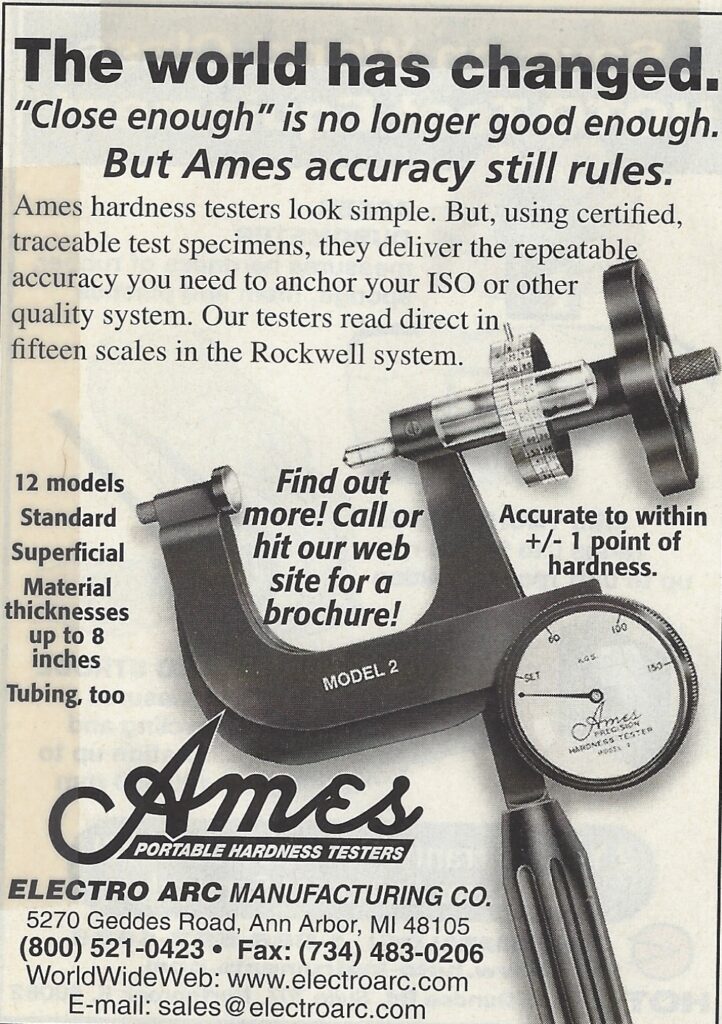

This kit contains everything you need to take your portable hardness tester with you in a secure and durable case. Ames portability lends itself to the appeal of using Ames portable hardness testers. Easy to use with one hand, easy to learn to use, and applicable in a number of work environments. Ames portable Rockwell testers have been manufactured continuously under the Ames name for over seventy years and for over fifty years under Electro Arc (now owned by Stillion Industries). They are guaranteed to comply with ASTM standard E-110 for testing hardness in Rockwell scales, with no conversion needed.

All Ames testers are 100% made in the USA, now 97% of the parts are machined by Stillion Industries. All Ames testers are assembled, tested, and calibrated onsite at our facility in Dexter, Michigan.